This guide contains directions for wiring a Voron Trident 250 using the pre-cut, pre-terminated cables included in the LDO kit. This wiring guide is applicable to both Rev A and Rev C kits - differences between Rev A and Rev C wiring will be indicated where necessary. Important! Mains wiring should only be performed by certified personnel trained in local regulations and safety standards. If at any point you find the images in this guide to be too small, you can check out the source images from this github location.

¶ Tools

Here is a short list of tools you should prepare:

- 2.5mm Flat head screwdriver (included in kit), this screwdriver is used to manipulate the UK2.5N terminals.

- PH2 Phillips screwdriver (not included in kit), this screwdriver is used on the power supply, SSR, and controller screw terminals.

- Multimeter (not included in kit), used to check connectivity.

¶ Pre-Wired Items

The following items should have pre-cut lengths, labels, and crimped connectors:

- Heatpad, joined with thermal fuse and installed on bed.

- Hotend Thermistor

- Hotend Cartridge

- Hotend Fan

- Print Cooling Fan

- Z Probe

- Toolhead PCB cable (Remove any zipties before installation into the cable chain)

Certain stepper motor cables are purposely left longer than needed for people with different setups. You may choose to cut them or leave them as is during wiring.

¶ Above Deck Wiring

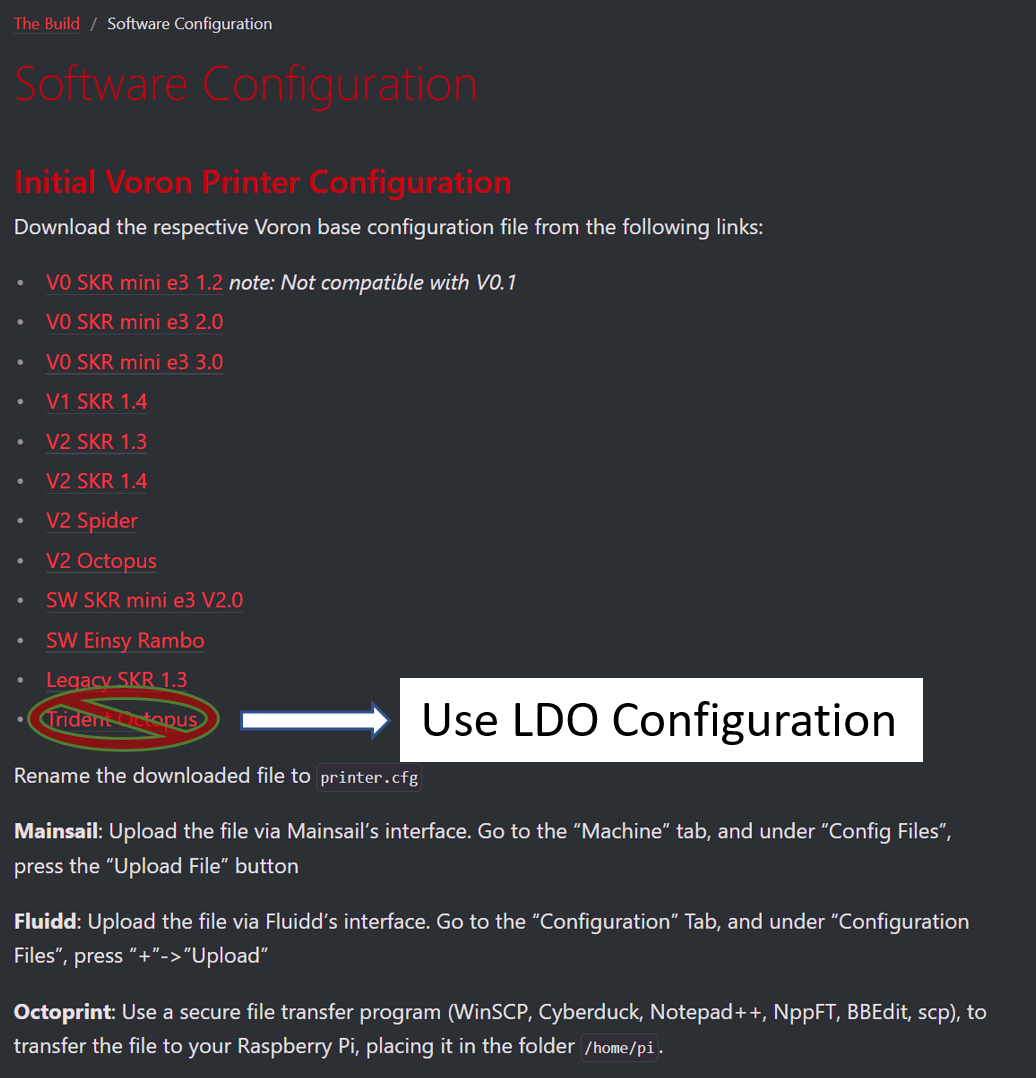

¶ Wiring the Toolhead PCB (Rev. A)

The Rev. C kit contains parts to build the Stealthburner + Clockwork 1 toolhead. For more information on these PCBs, refer to the wiring kit page and github repository.

The main toolhead PCB attaches to the sides of the Clockwork 1 extruder. Use two M3x8 screws to install the PCB to the Clockwork 2 extruder. Remember to place a spacer between the PCB and the extruder.

- Connect the inductive probe or Klicky cable to the PROBE port. Note that for Klicky, the 24V pin is not connected. If using the TAP probe, make sure the probe PCB is compatible with 24V.

- Connect the hotend heater/cartridge to the screw terminal connector - polarity does not matter here. If you have a hotend with a integrated heater element, you may need to crimp ferrules onto the heater cables. The ferrule type to use is E0508.

- Connect the hotend thermistor to the TH0 port. A thermistor is provided in the kit (Semitec 104NT); if you have a hotend with a integrated thermistor, you may need to crimp a connector on the thermistor cable. The connector type to use is JST-XH2.5 two pin.

- Connect the extruder motor to the E-STEP port.

- Connect the 5015 Blower Fan to the PCF port. If you are using your own fan, use the polarity labelled on the PCB to crimp a 2pin JST-XH2.5 connector to your fan cable.

- Connect the 4010 Axial Fan to the HEF port. If you are using your own fan, use the polarity labelled on the PCB to crimp a 2pin JST-XH2.5 connector to your fan cable.

Additional notes about the afterburner toolhead PCB:

- The XES (X endstop) port is not used in this build.

- Due to the design of the toolhead PCB, the probe 24v pin is not configurable using jumpers on the mainboard.

- Due to the design of the toolhead PCB, the fan port voltage is fixed at 24V both the PCF and HEF fans.

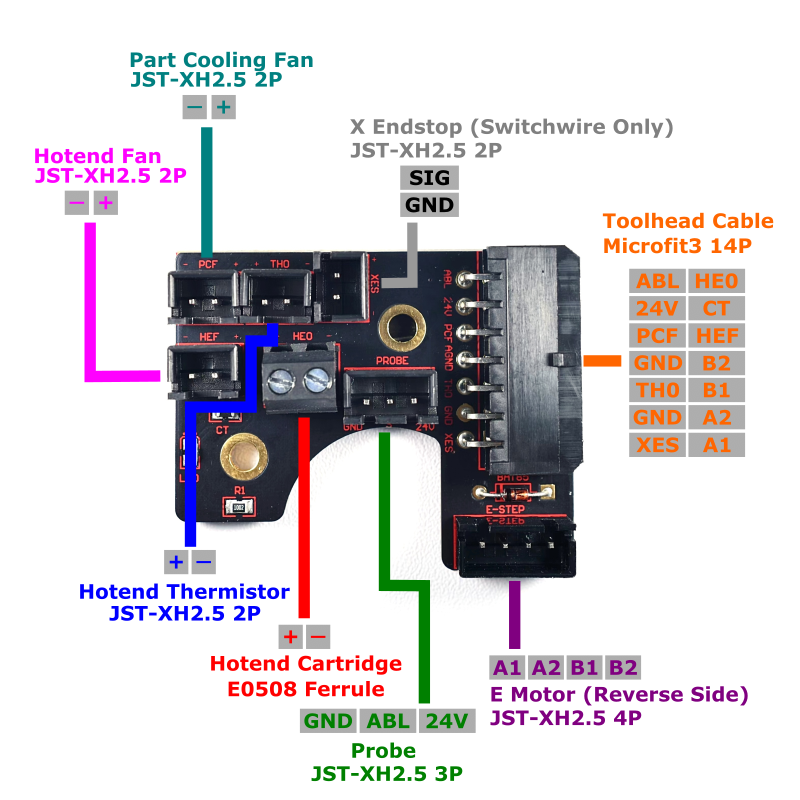

¶ Wiring the Toolhead PCB (Rev. C)

The Rev. C kit contains parts to build the Stealthburner + Clockwork 2 toolhead. A two piece PCB based on hartk's two piece toolhead PCB design is provided to aid in wiring. For more information on these PCBs, refer to the wiring kit page and github repository.

The main toolhead PCB attaches to the sides of the Clockwork 2 extruder. Use two M3x8 screws to install the PCB to the Clockwork 2 extruder. Remember to place a spacer between the PCB and the extruder.

- Connect the inductive probe or Klicky cable to the PROBE port. Note that for Klicky, the 24V pin is not connected. If using the TAP probe, make sure the probe PCB is compatible with 24V.

- Connect the hotend heater/cartridge to the screw terminal connector - polarity does not matter here. If you have a hotend with a integrated heater element, you may need to crimp ferrules onto the heater cables. The ferrule type to use is E0508.

- Connect the hotend thermistor to the TH0 port. A thermistor is provided in the kit (Semitec 104NT); if you have a hotend with a integrated thermistor, you may need to crimp a connector on the thermistor cable. The connector type to use is JST-XH2.5 two pin.

- The Stealthburner PCB does not come with an onboard thermistor like previous versions. Instead, we will connect an external thermistor to the port labelled CT. The chamber thermistor provided in the kit is identical to the hotend thermistor in model and appearance but is labelled with “CT”. Remember to use this cable cover which comes with a holder for the chamber thermistor.

- Connect the extruder motor to the E MOTOR port located at the back of the PCB.

- Attach the 14pin Toolhead cable and 2pin Neopixel cable to their respective ports - you should do this after installing the Clockwork 2 extruder onto the X carriage.

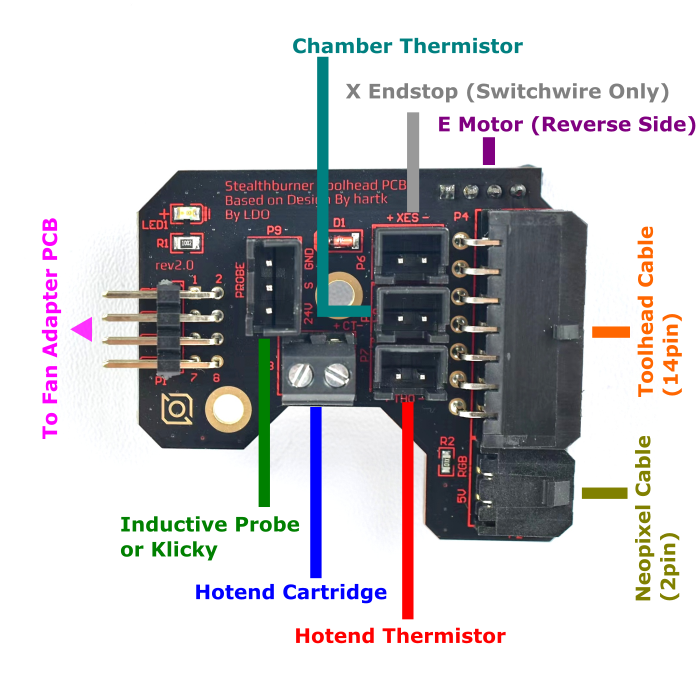

The fan adapter PCB attaches to the rear of the Stealthburner main body. Use two M3x6 screws to install the PCB directly on the back of the 5015 fan.

- Connect the 5015 Blower Fan to the port P4. If you are using your own fan, use the polarity labelled on the PCB to crimp a 3pin JST-PH2.0 connector to your fan cable.

- Connect the 4010 Axial Fan to the port P2. If you are using your own fan, use the polarity labelled on the PCB to crimp a 3pin JST-PH2.0 connector to your fan cable.

- Connect the Neopixel Chain to the port P3.

- The 2x8 headers on the two PCBs connect to each other when your install the Stealthburner main body to the rest of the toolhead - this allows you to easily attach and detach the stealthburner when performing maintenance or upgrades. Make sure the two headers line up properly each time they are connected.

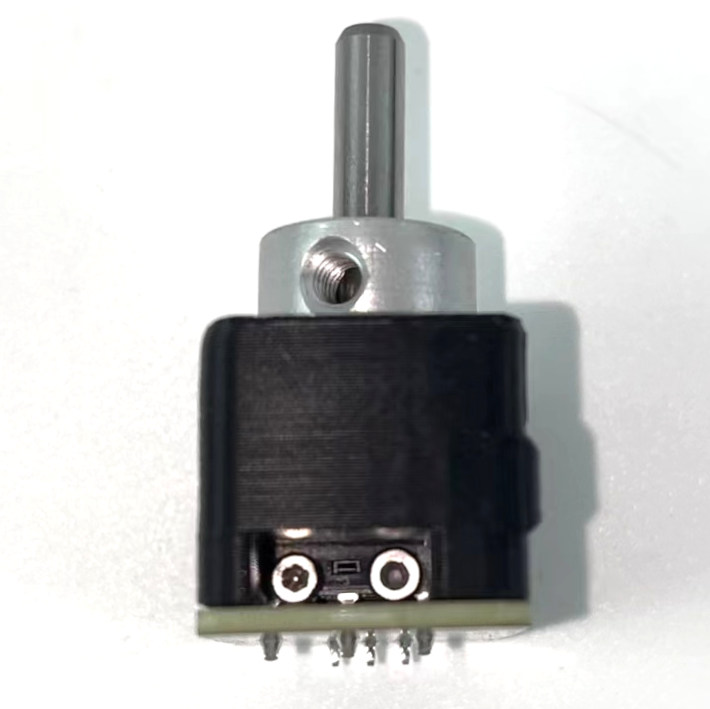

¶ Assembling the Z endstop (a.k.a. Nozzle Probe)

Our nozzle probe is slightly different from the official endstop, use our printed part.

Use two M2x10 self tapping screws to install the PCB onto the printed part. The screws go through the two holes on the D2F switch and fasten sideways into the printed part.

The final result looks like this. Use two M3x25 SHCS to mount the nozzle probe onto the printer. Remember to install one set screw into the pulley, but do not overtighten it. The screw screw is there to ensure that the shaft cannot fall out of the probe body; however it should not be so tight as to impede the shaft from freely moving up and down.

¶ Wiring the XY endstop

The XY endstop cable has the same 4pin JST-XH connector on both ends but only one end has a label. We recommend connecting the end with the label to the controller and the end without the label to the XY endstop PCB.

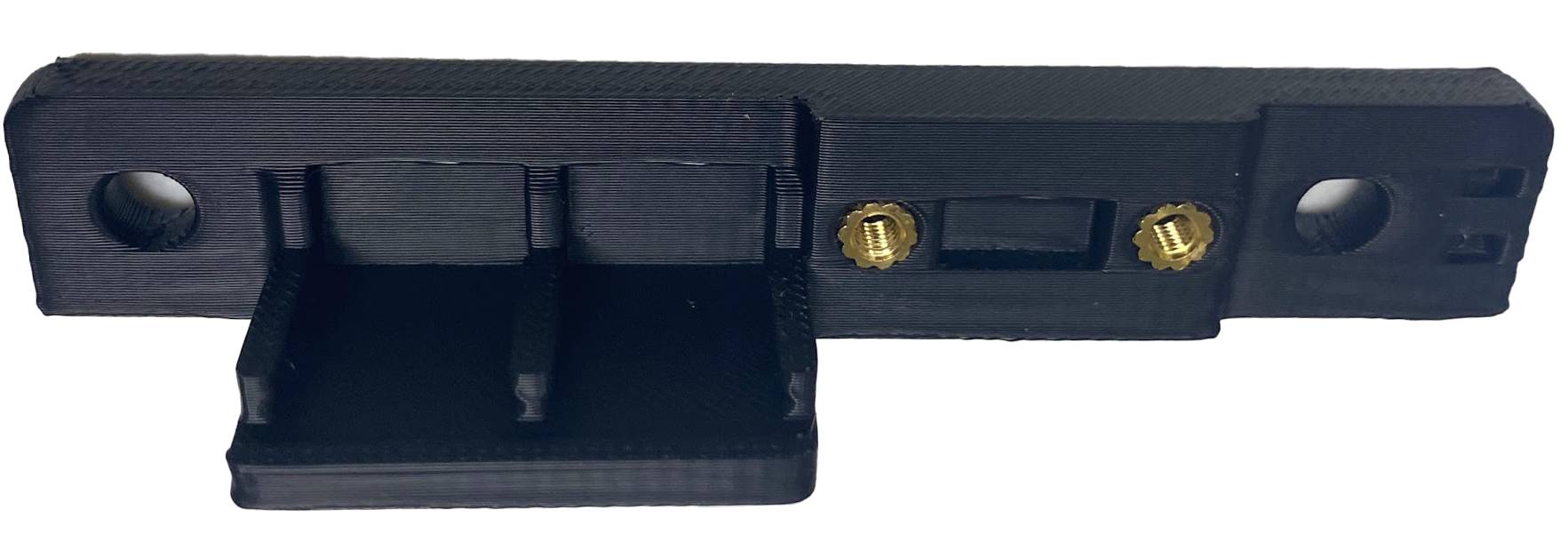

¶ Wiring the Build Plate

Attach the WAGO terminals and 2x2 splicing PCB to the heatbed wiring mount. Use two heat set inserts from the front of the printed part then use two M3x6 BHCS screws to fasten the PCB. Use two M5x10 BHCS screws to fasten the mount onto the frame. Finally there is a M4 screw and serrated washer directly fastened to the aluminum plate - this is where you attach the bed PE (protective earth) cable to ground the build plate. Remove the serrated washer from the aluminum plate, this will be used later to attached the ground wire to the frame.

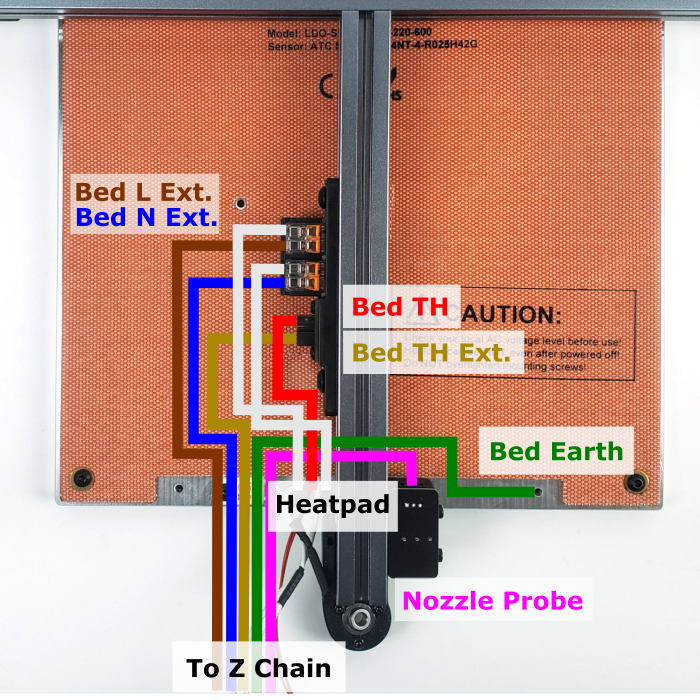

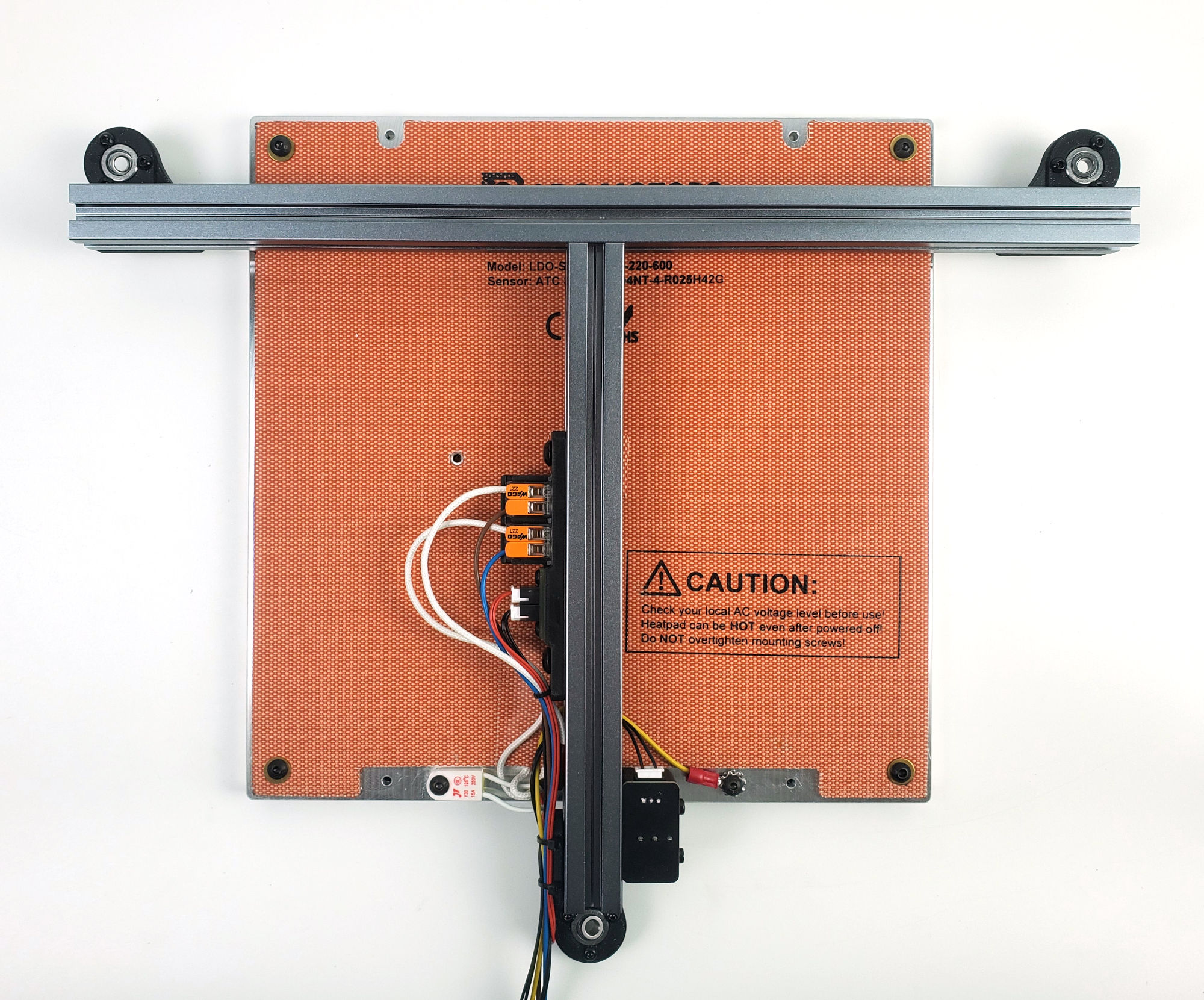

After installing the Z endstop and heatbed wiring mount to the bed frame, follow the diagram below for wiring:

Remember to use zipties to anchor the cables near the z chain, The end result should look something like this:

¶ Insulating the Z Probe

Our kit comes with a small strip of fiber glass tape. This tape is used to help insulate the Z probe from radiative heat from the the hotend. We recommend covering the front and sides of the probe with at least 2 layers of this tape. Do not cover the back or the bottom of the probe, if you have problems triggering the probe, try removing bits of the tape as it may be interfering with probe sensing. Optional: consider cutting an opening in the tape, around the LED of the Z probe - this will allow you to see the LED light up when the Z probe is triggered.

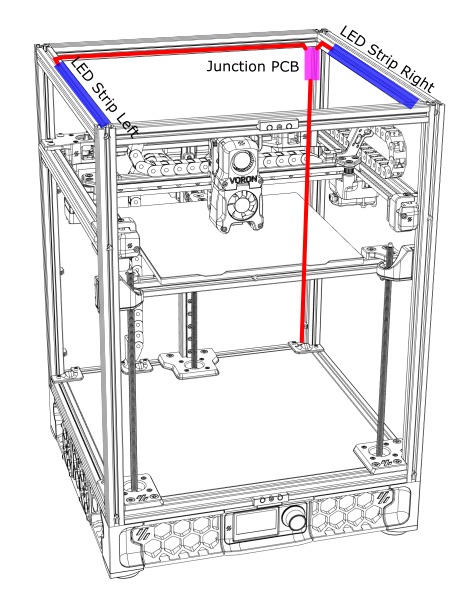

¶ Routing the LED strips

Our kit includes two LED strips to install as ceiling lighting for your printer. Please remember to mount using the printed part to prevent a short with the extrusion and mount using M3 hammerhead nuts (or t-nuts) and M3x8 SHCS screws.

Print the bar clips from the print guide and mount them at the top left and right extrusions. We recommend following the routing path shown in the diagram below:

Remember to cover the slots where your LED cables are routed with the extrusion covers provided with the kit.

¶ Below Deck Wiring

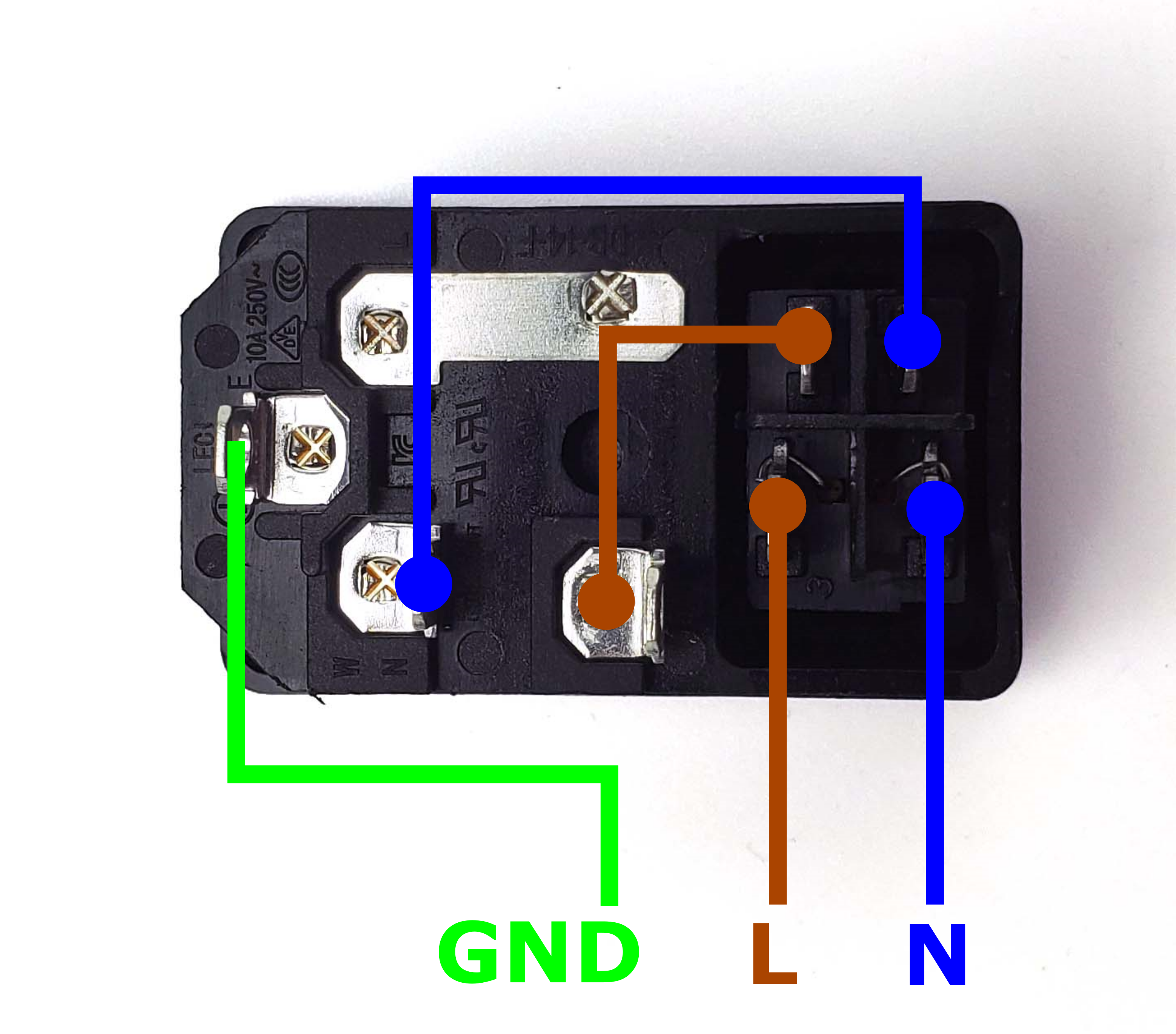

¶ Preparing the Inlet

Your kit should include a pre-wired AC inlet. Double check that the wiring correct, the final layout should be as follows:

Take the inlet cable included in the kit and attach the wires using the above layout as reference. When wired correctly, your live wire will be protected by a fuse, and the switch on the front side of the inlet will operate correctly (lights up when turned on).

¶ Preparing the Power Supply Unit

The 24V power supply unit that comes with the kit contains a switch on the side to select between 120V and 230V. Flick the switch to the correct value* before powering it on! Failing to do so can destroy the power supply!

* EU Customers may receive the Meanwell RSP-200-24 to comply with local regulations, this model has a universal AC input so there is no switch to flip in this case.

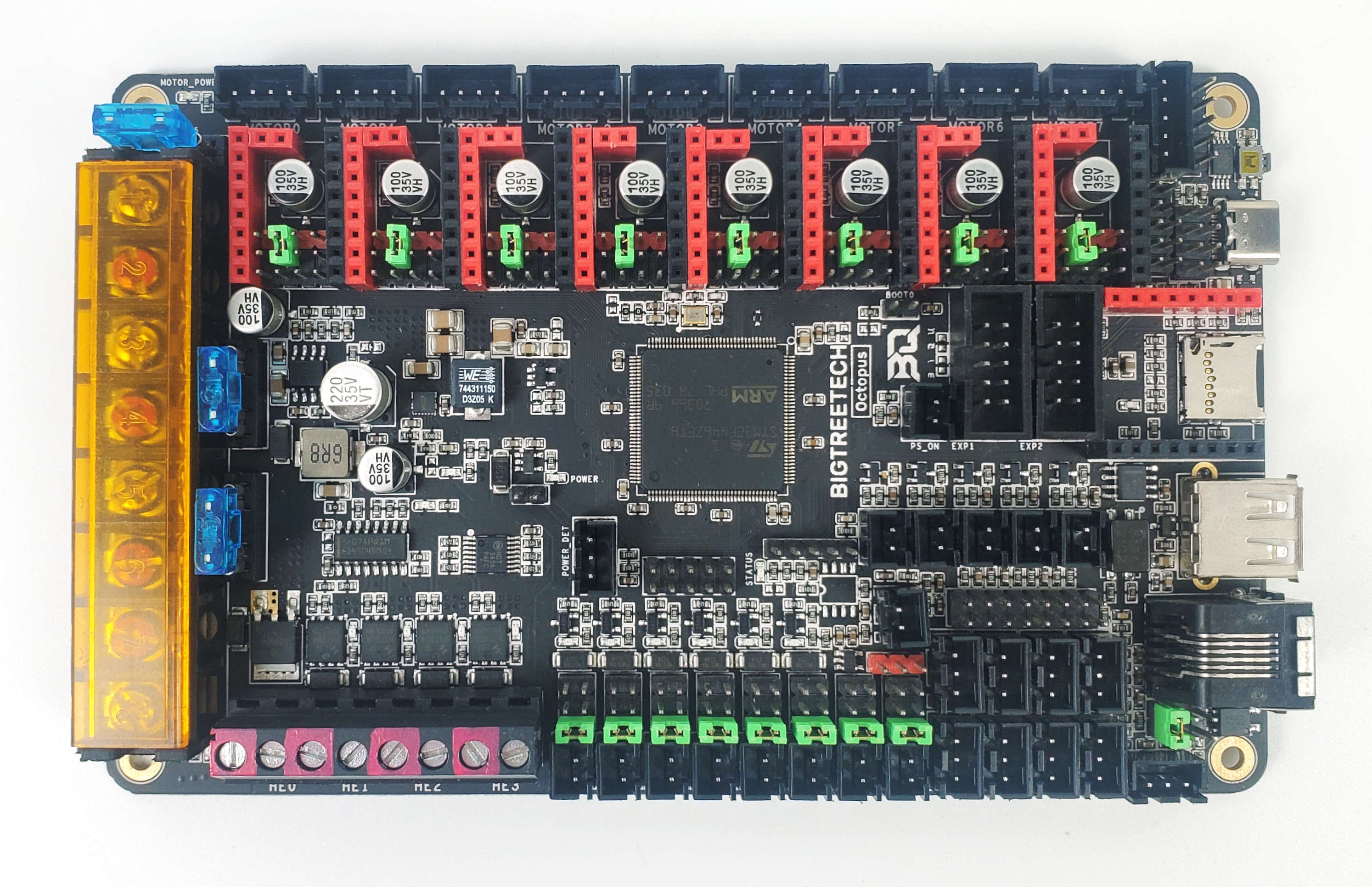

¶ Preparing the Controller (BigTreeTech Octopus)

Before installing the controller board, we need to prepare a few things:

- Make sure the jumpers are installed correctly (refer to the photo below)

- Install the stepper drivers onto the motor slots: Motor 0 to Motor 5 (Motor 6, 7 is unused)

- Do NOT the change the voltage selection jumpers from what is shown (24v) for the toolhead fans. Mixing voltages will damage the Octopus controller. Changes to the other jumpers will NOT change voltage from 24v to the toolhead PCB which could damage non-24v components.

- Optional, but highly recommended: mark terminals on the PCB. In the photo below, we used a red marker to colour all the positive screws in terminals. This will help us avoid any polarity mistakes down the road.

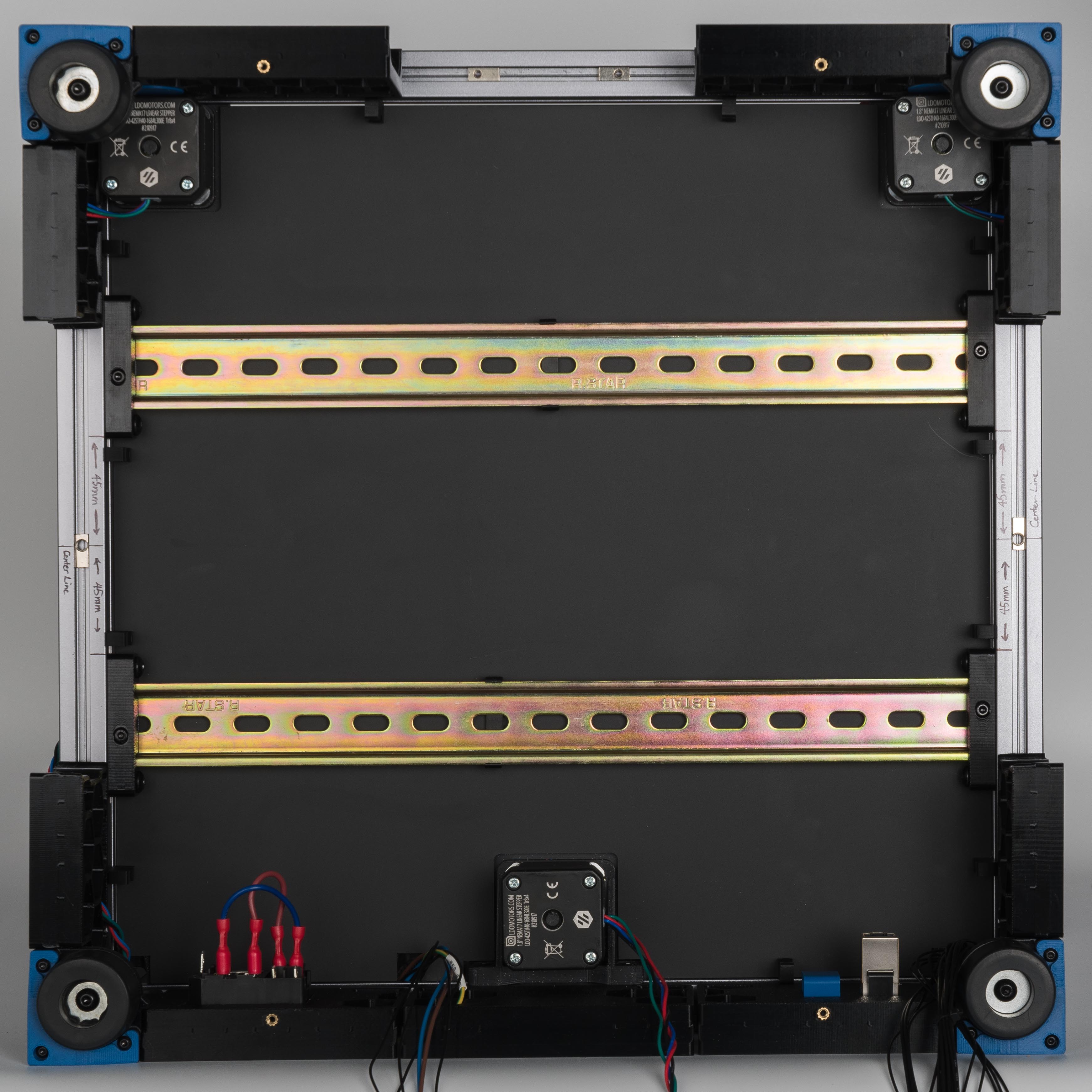

¶ Installing the DIN Rails

Our first step is to install the DIN rails. Note the orientation of the Z stepper motors*. Rotating them now will make it easier to route the motor cables later. Also note the positioning of the deck supports around the edges of the deck panel.

* You may receive Z motors with and a detachable cable as opposed to integrated cables as shown in the photos.

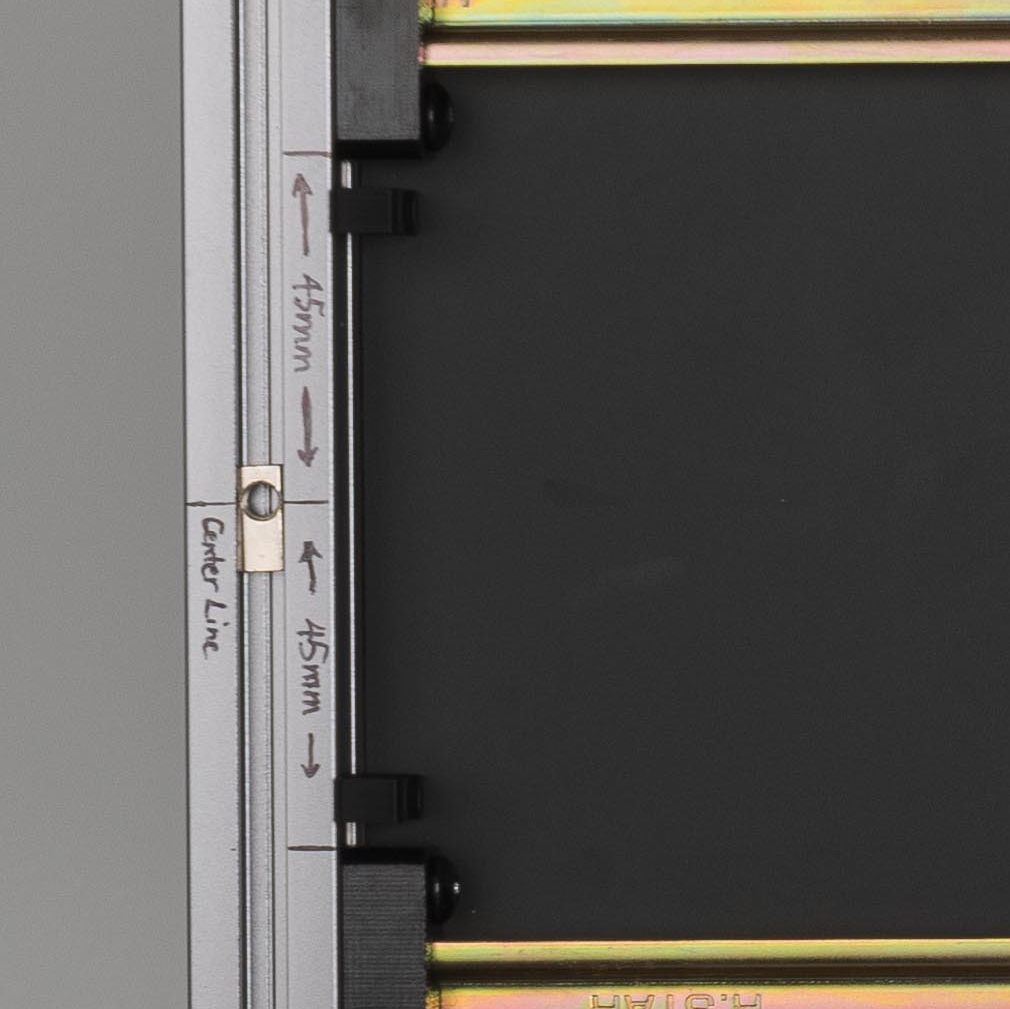

The positioning of the DIN rails is important here - the edge of the DIN frame mounts should be 45mm away from the center of the side frames:

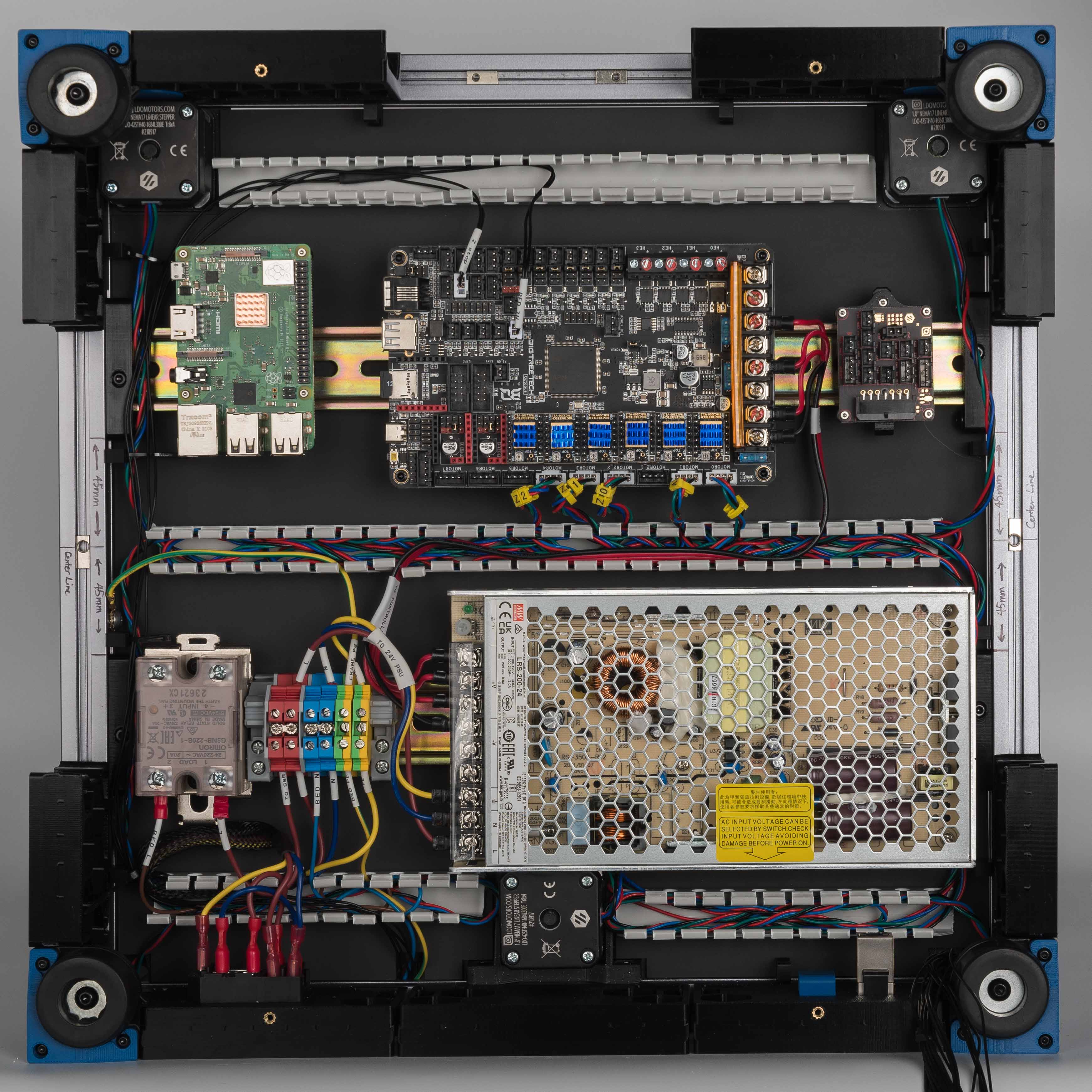

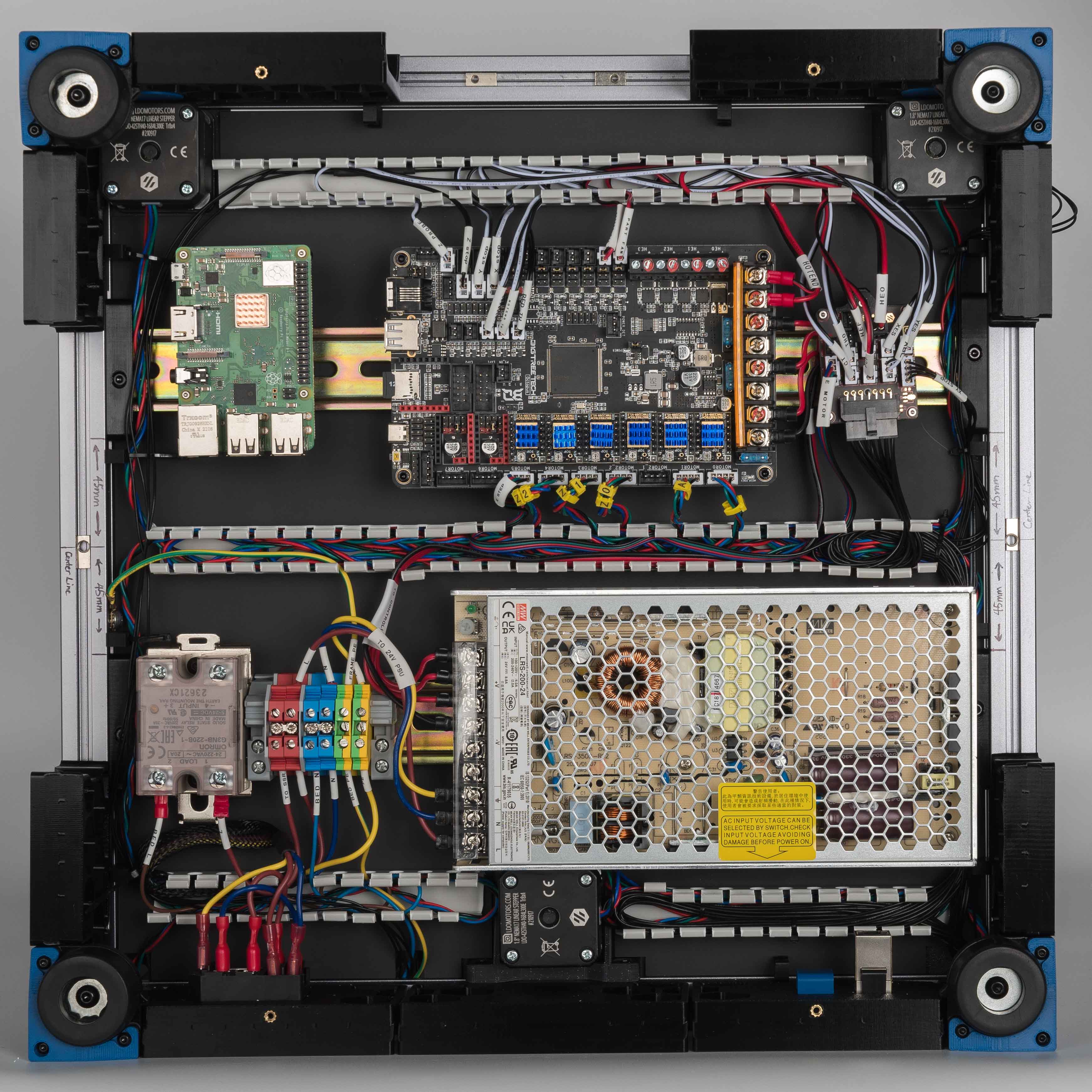

¶ General Placement

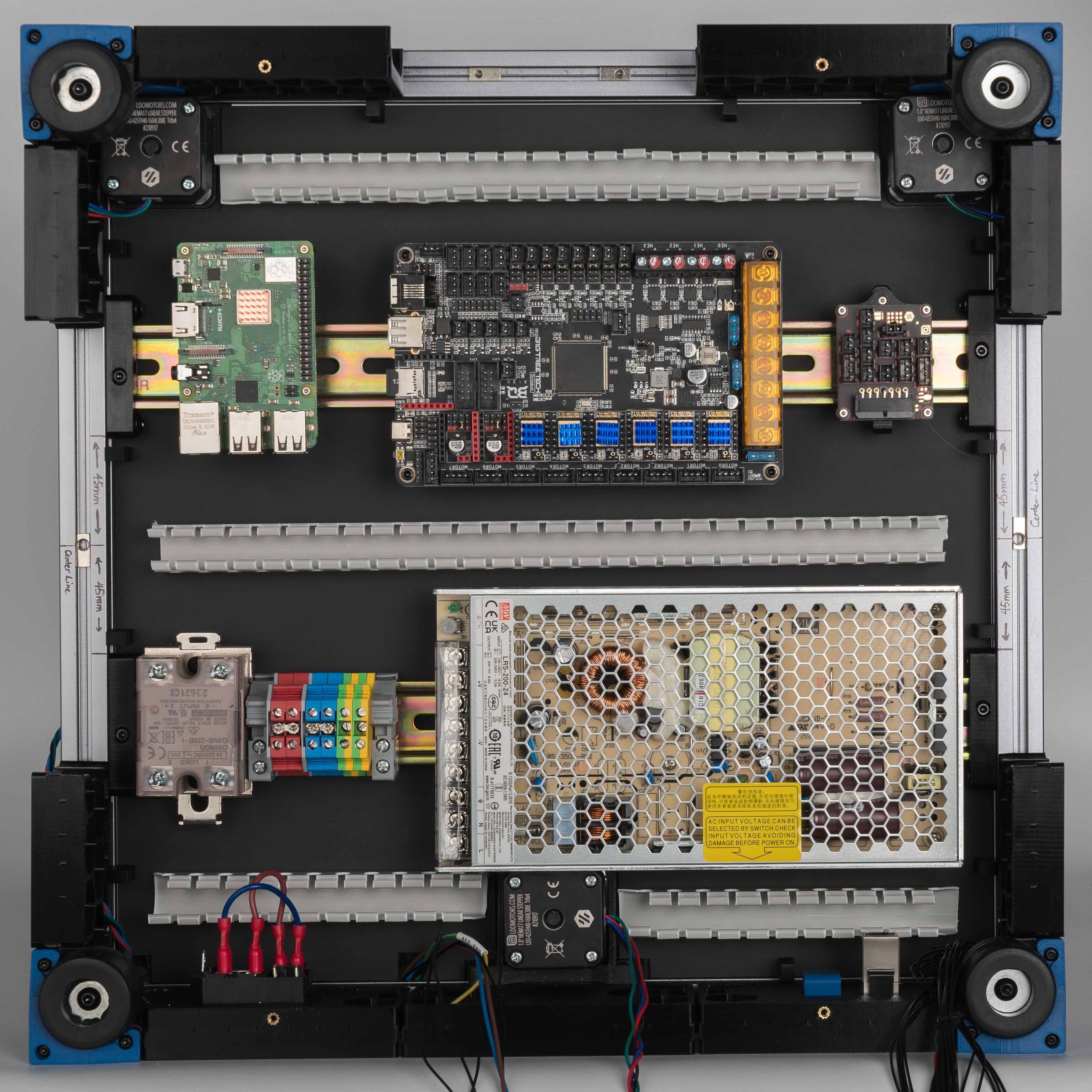

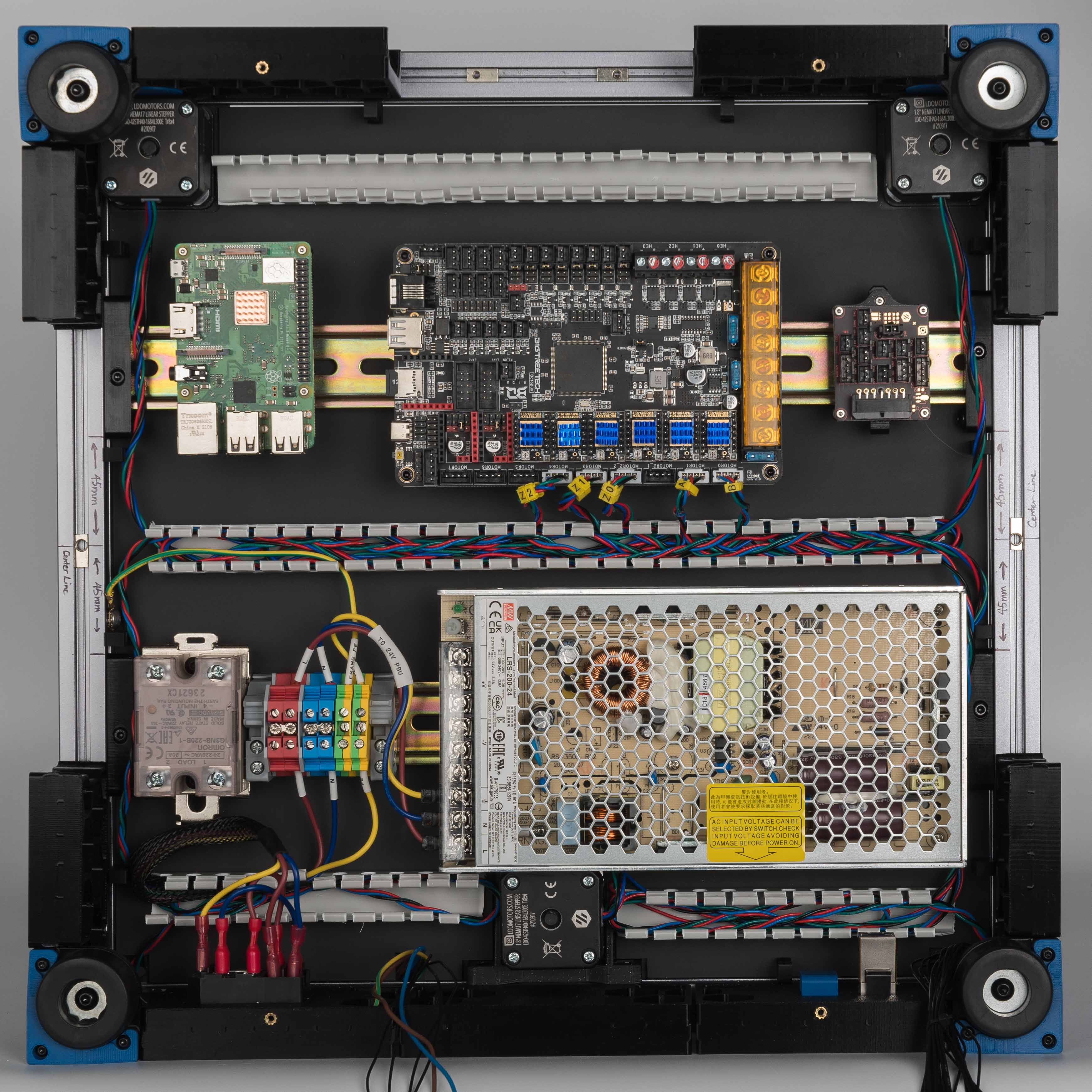

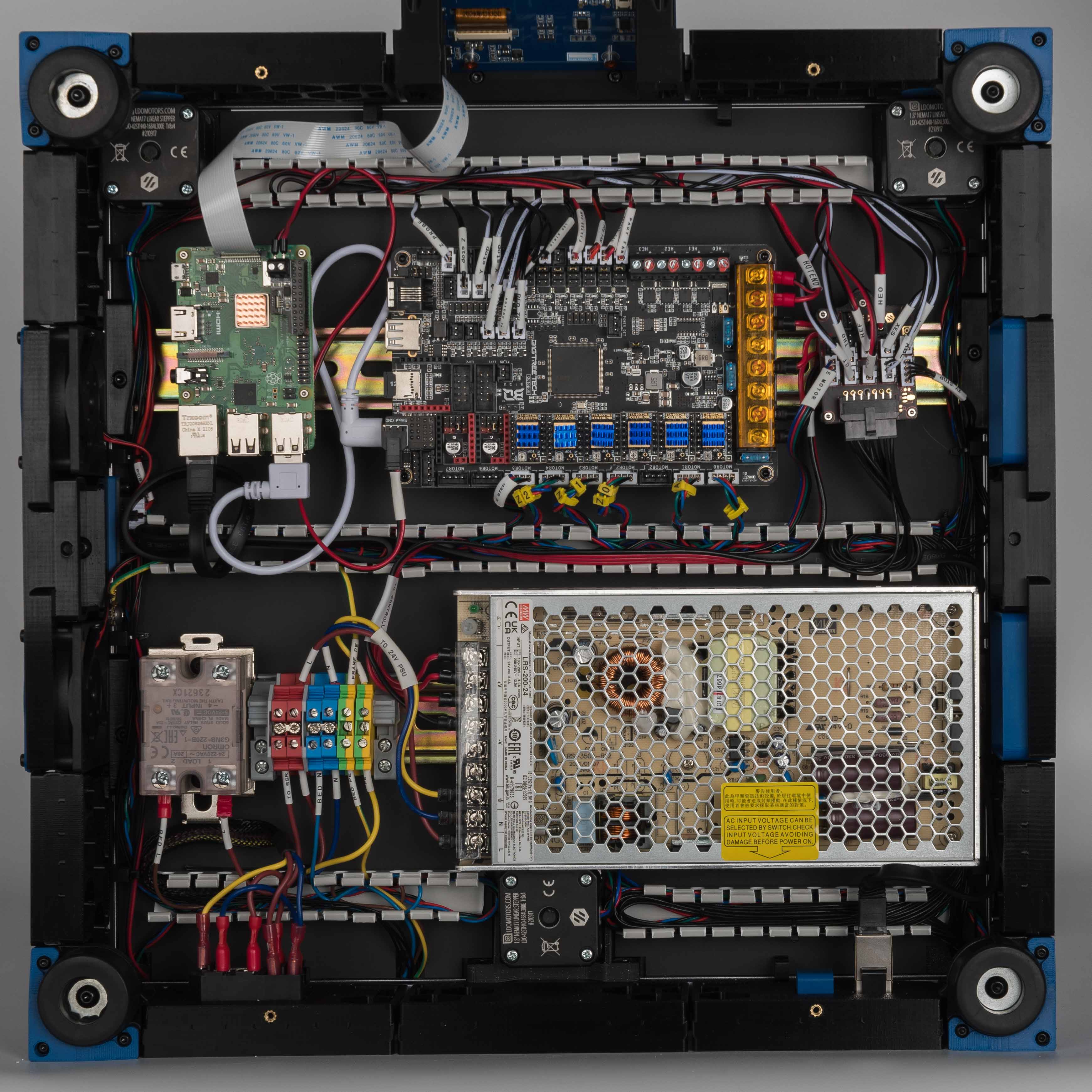

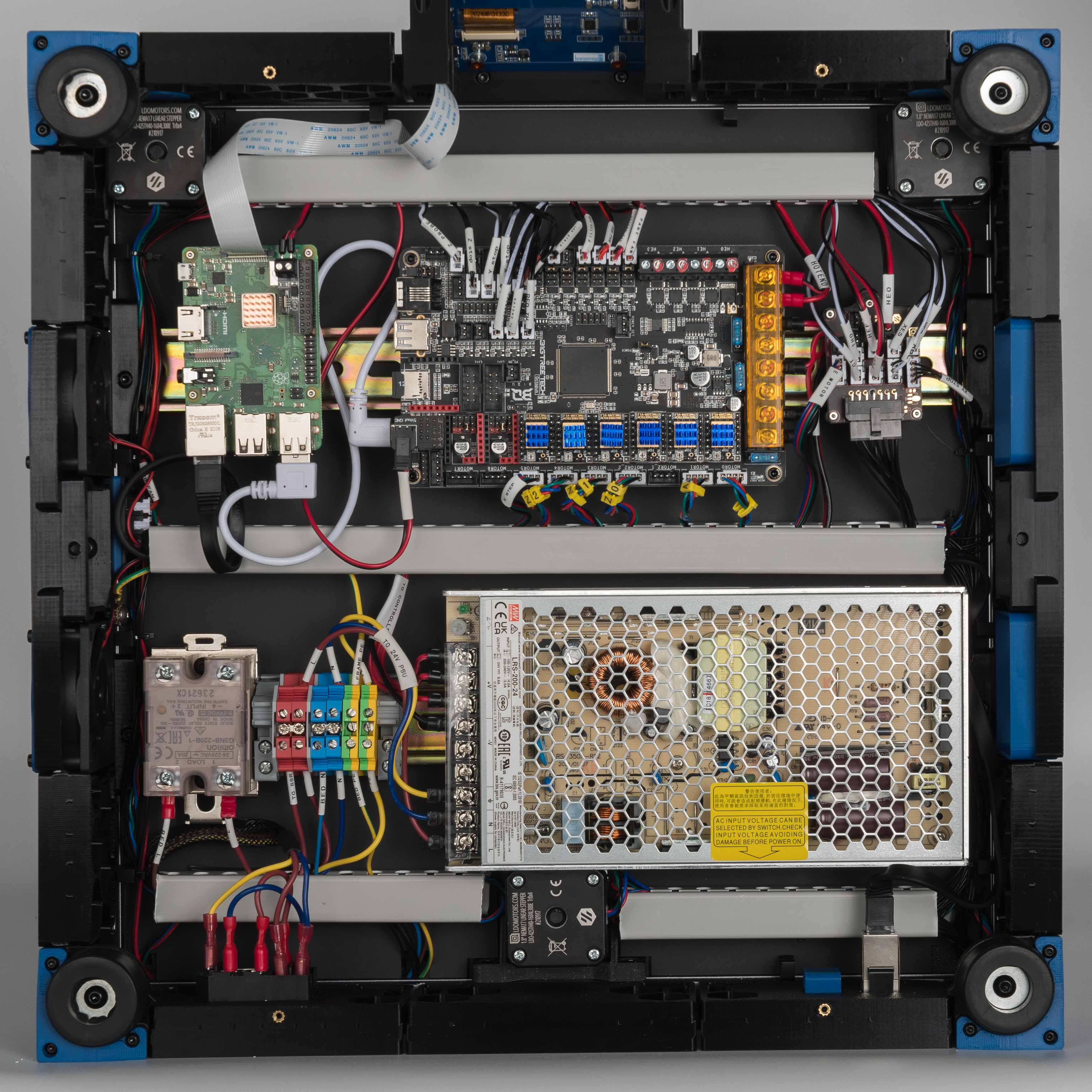

In this step, we will place all the major electronic components and install the wire ducts.

- Place the electronic components as shown in the image below. Make sure to leave as much space as possible between the 24V power supply and UK2.5 terminals by placing the terminals close to the SSR (refer to the UK2.5 terminal guide for installation).

- Mount the SSR to the metal SSR mount using two M4x6 BHCS screws.

- Use the provided VHB tape to install the wire ducts. Follow the instructions below (in order) for cutting and placement of each duct:

Top (Front). Use a piece of 33cm duct and cut it such that it can fit between the two front Z motors. Place it roughly as shown in the picture.

Middle. Take another piece of 33cm duct and place it roughly between the 24V power supply and Octopus controller. Try to make sure there is at least a 2.5cm gap between the Octopus and wire duct.

Bottom (Rear). Take the last piece of 33cm duct and cut it into two segments that will between on either side of the rear Z motor and below the 24V power supply. The two segments do not have to be perfectly aligned, but the right segment should have a small gap between itself and the power supply.

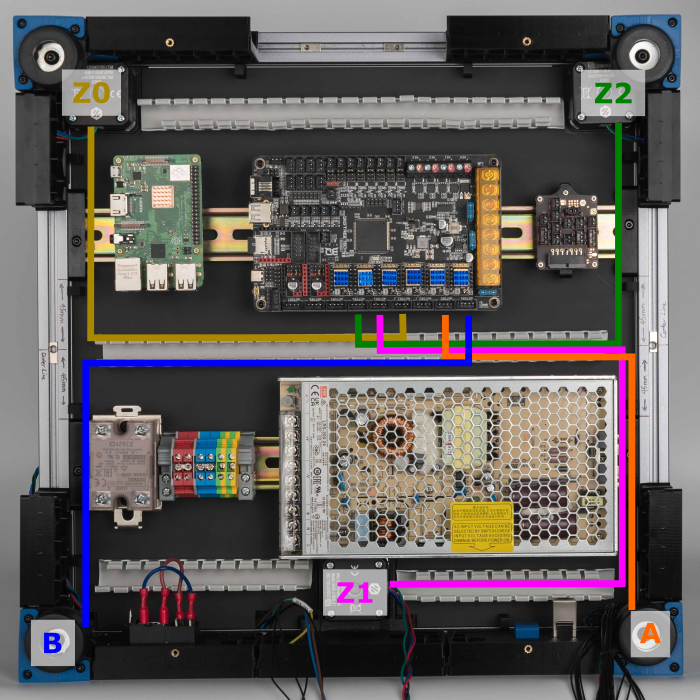

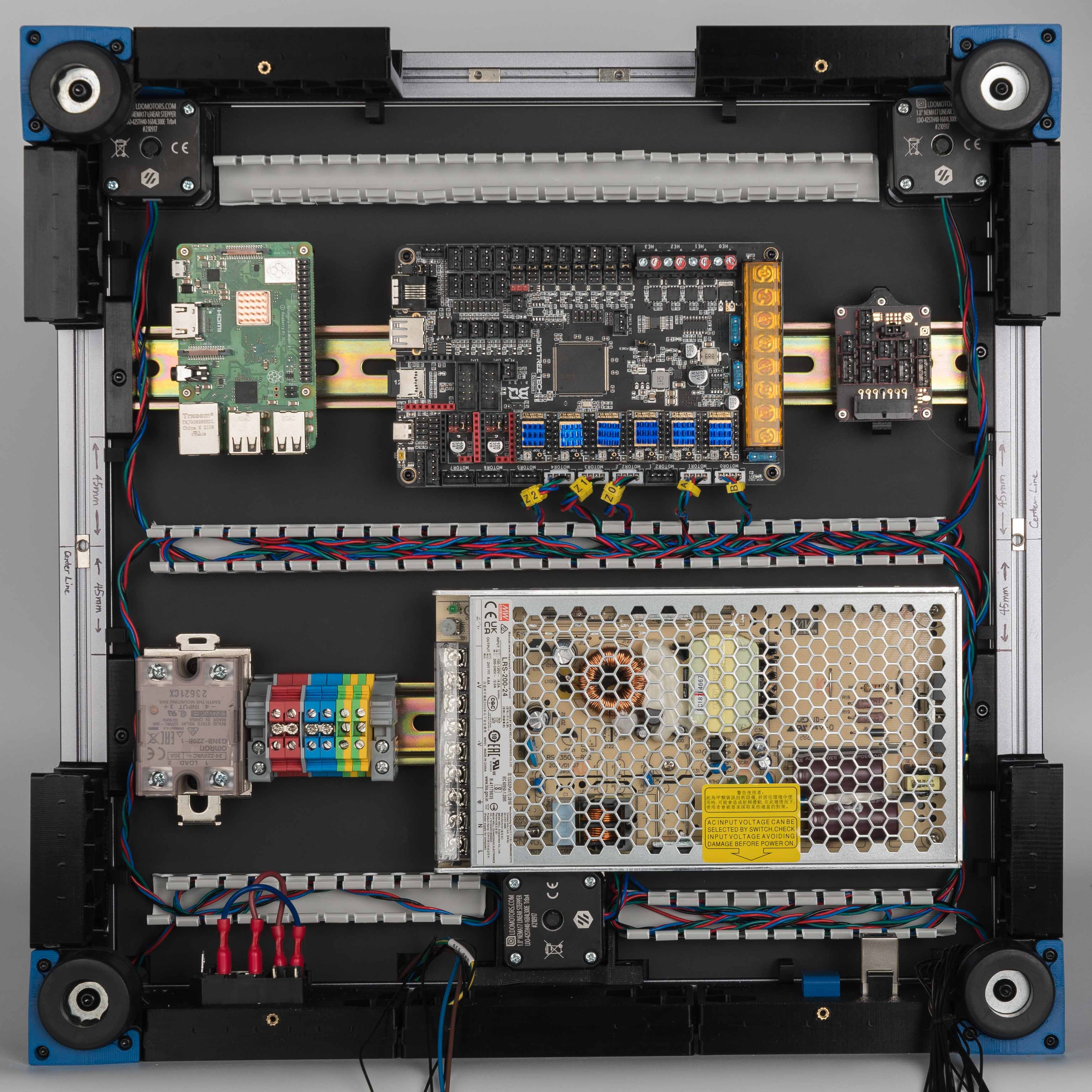

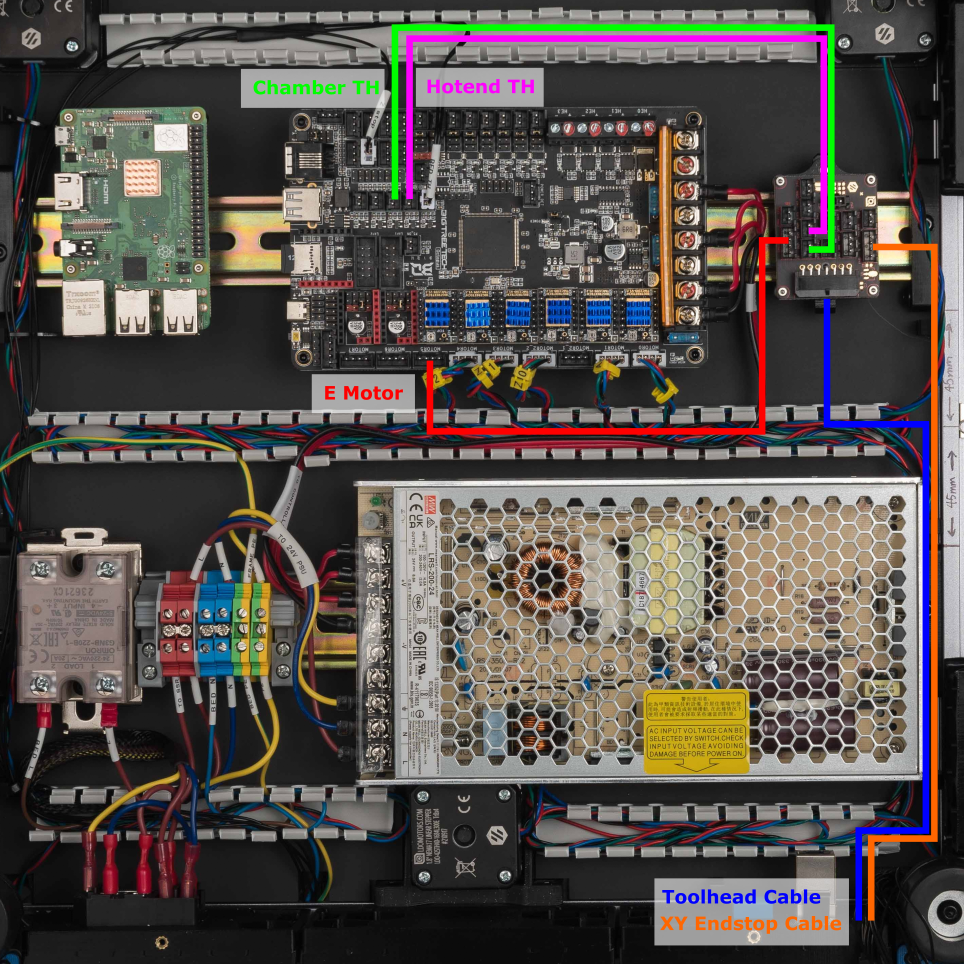

¶ Connecting Steppers

In this step, we will install all the stepper motor cables (except for the E motor). We recommend taking advantage of the included cable tags to label your stepper cables. Follow the table and diagram below:

| Stepper Motor | Physical Position* | Controller Position |

| A | Rear Right | MOTOR1 |

| B | Rear Left | MOTOR0 |

| Z0 | Front Left | MOTOR2_2 |

| Z1 | Rear | MOTOR3 |

| Z2 | Front Right | MOTOR4 |

*All positions are specified as if standing in front of an upright printer and looking towards it.

The end result should look like this:

¶ Connecting Inlet and PSU

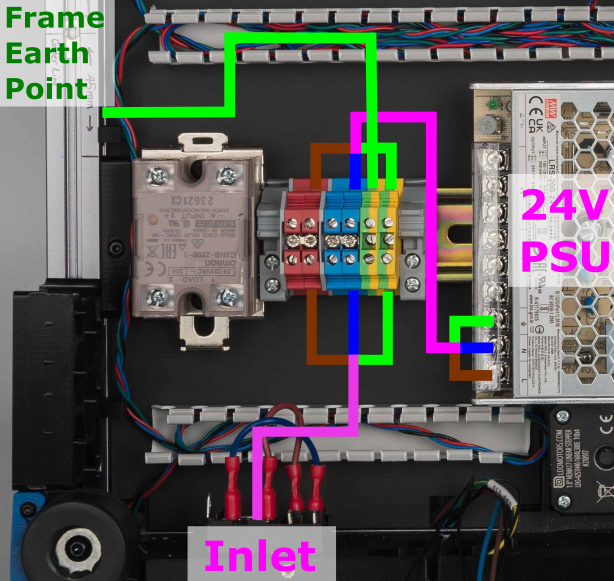

In this step we will connect the AC Inlet, the terminals and 24V power supply. Refer to the following diagram:

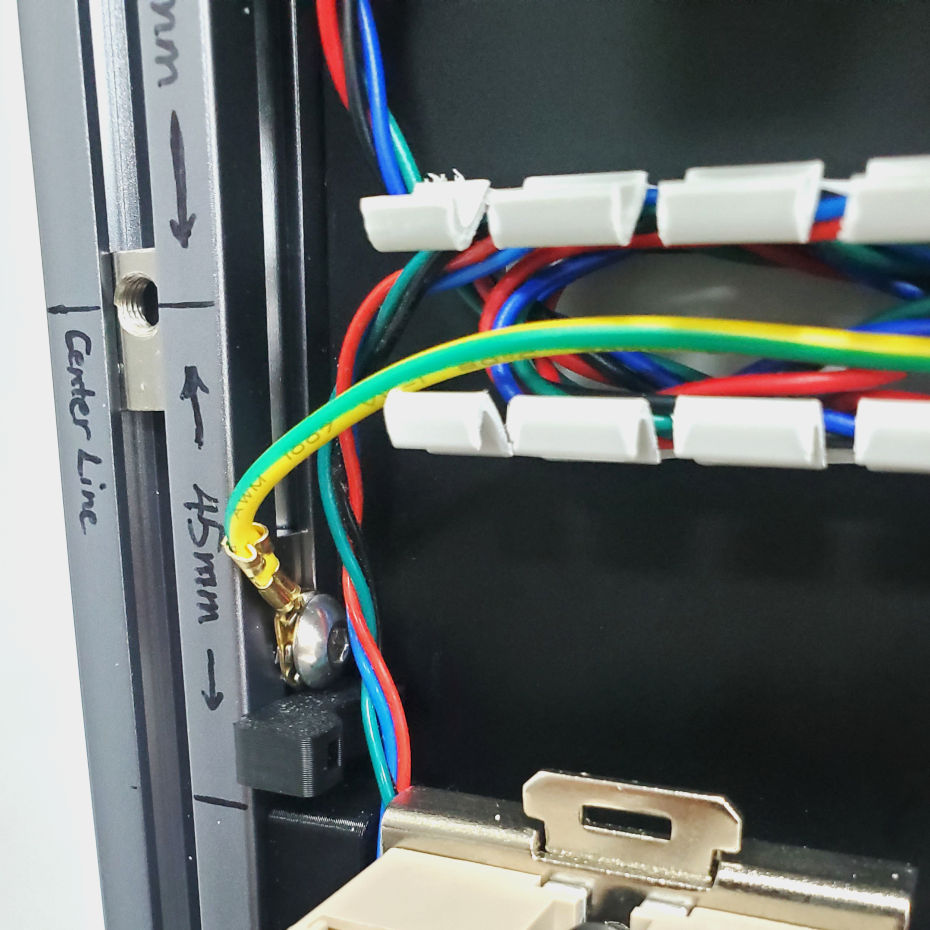

The grounding wire should be attached using two serrated washers and screwed into the frame. This will ensure a secure electrical connection between earth and the printer frame:

The end result should look like the following:

¶ Checkpoint #1

Before moving on to the next step, let us check all the wiring so far. Incorrect wiring of AC/mains can be dangerous - therefore, always double check your work, and then triple check it once more:

- Remember to check everything without the power cable plugged into the inlet!

- Check that all colours match - blue wires should only go into blue terminals, red into red, green/yellow into green yellow and so on.

- Use a multimeter to check continuity between all nodes of the same colour - they should be shorted.

- Use the multimeter to check continuity between Live, Neutral, Earth - they should not be shorted with each other.

- Check that Earth on the inlet is shorted with the DIN rails and the build plate.

- Check again that the power supply voltage input switch is set to the correct value: 115V vs 230V

- After checking all of the above, plug in the power cable and switch on the inlet: The power supply should turn on and it's LED should light up.

- Switch off the inlet and remove the plug, we can now move on to the next step.

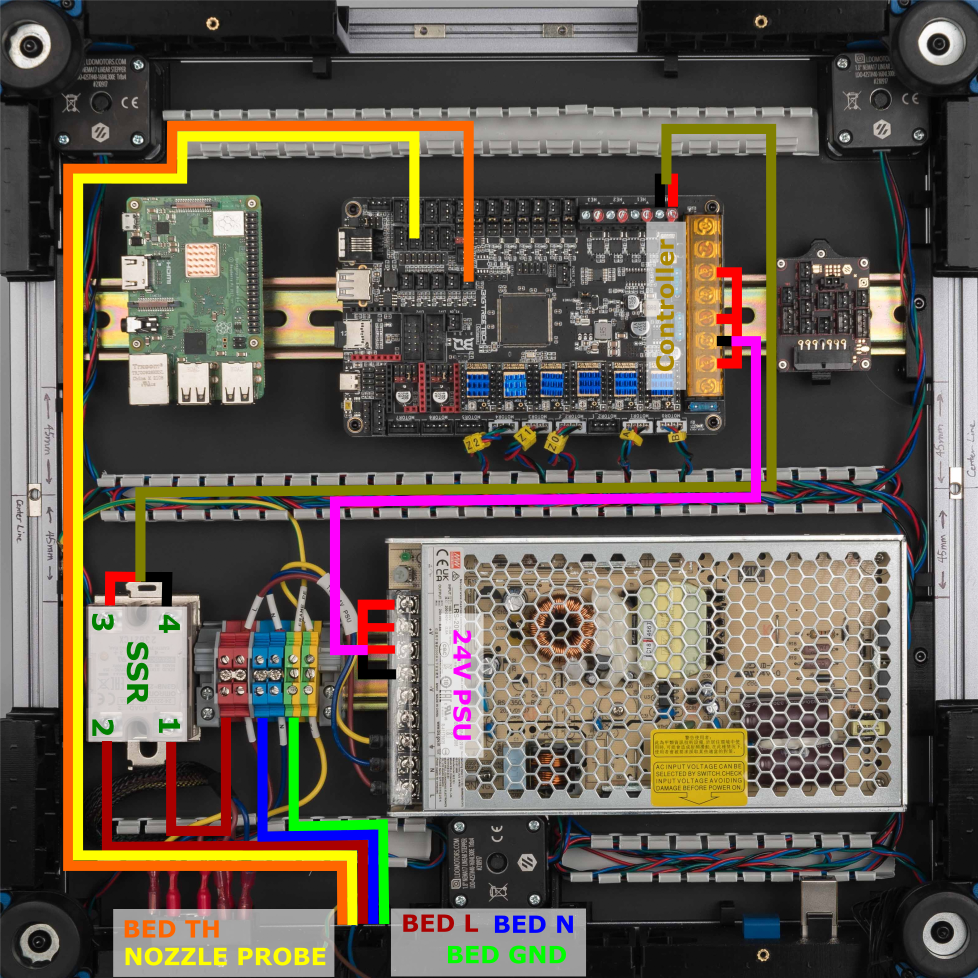

¶ Connecting 24V and Build Plate

In this step, we will connect the power supply to the controller board and make all the build plate connections.

First connect the following items according to the following table:

| Item | Cable Label | Controller Position |

| Bed Thermistor | BED TH | TB/PF3 |

| Bed Earth | BED PE | Earth (green/yellow) UK2.5 terminal |

| Bed Neutral | BED N | Neutral (blue) UK2.5N terminal. |

| Bed Live | BED L | LOAD (2) on the SSR. |

| Nozzle Probe | Z ENDSTOP | DIAG2/PG10 |

Make the remaining connections by following the these steps:

- Connect LOAD 1 on the SSR to a Live (red) UK2.5N terminal.

- Connect HE0 + and - terminals on the Octopus to 3 (+) and 4 (-) terminals of the SSR input. Note that the SSR end of the cable has larger fork connectors.

- Connect the + terminals of BED_POWER, POWER, and MOTOR_POWERin the Octopus to the three + terminals of the 24V power supply.

- Connect the - terminal of POWER in the Octopus to one of the - terminals of the 24V power supply.

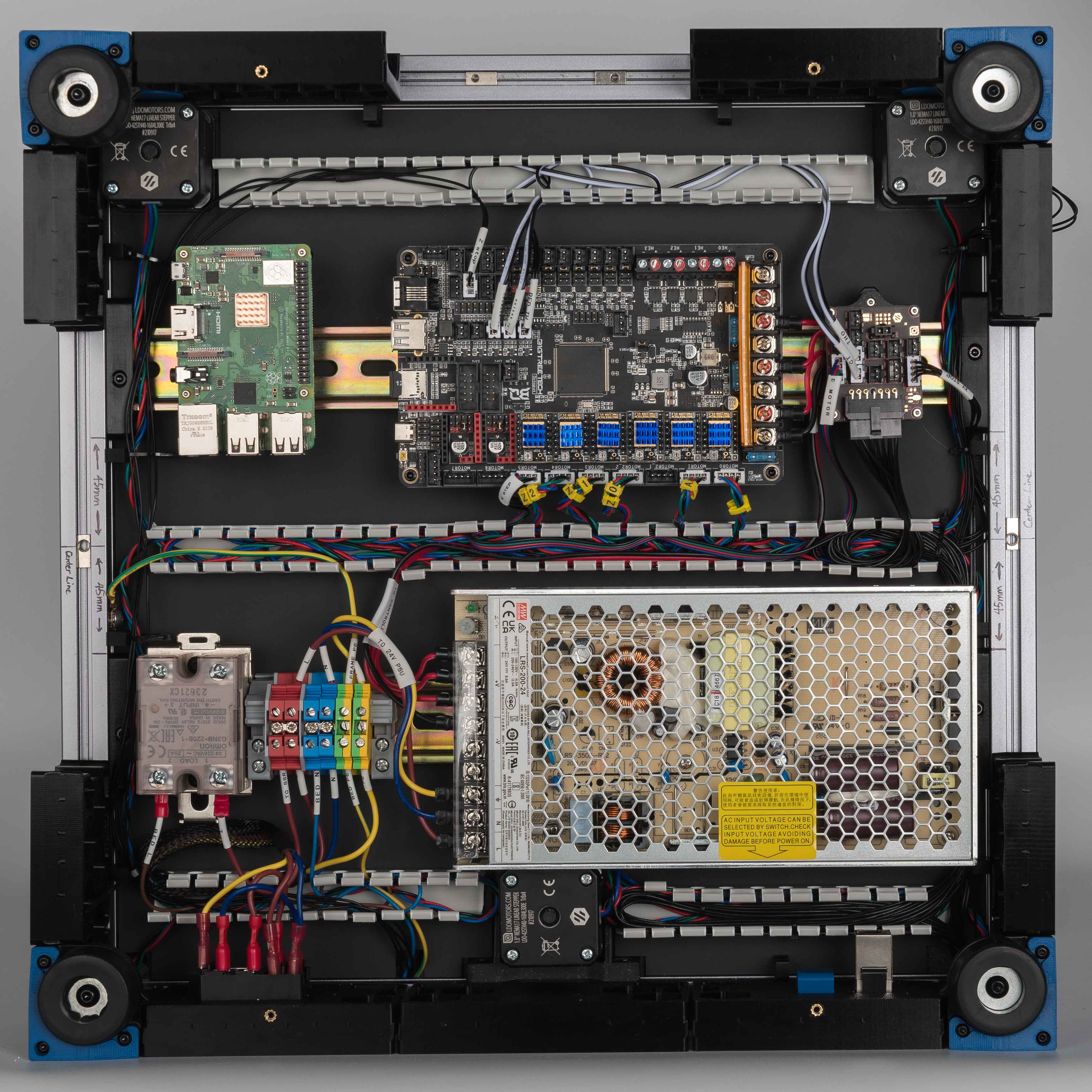

If in doubt, check the high resolution images here and here. The Octopus pinout can be found here. The final result:

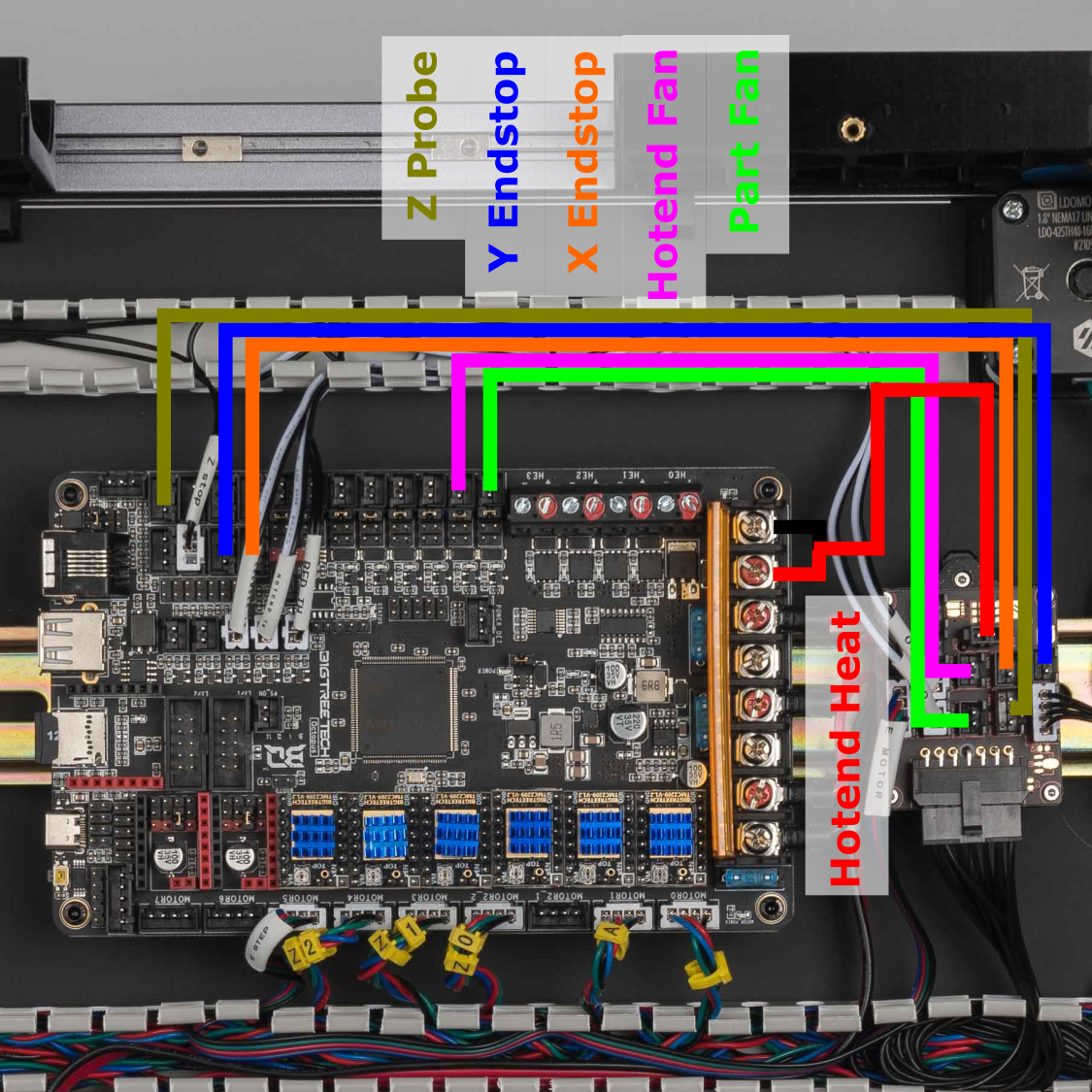

¶ Connecting the Toolhead Breakout Cables (Part 1)

We will now begin connecting the cables between the toolhead breakout PCB and the Octopus controller.

- Connect the 4 pin XY endstop cable to the 4 pin connector (Labeled GND X Y Vin) on the breakout PCB.

- Connect the 14 pin toolhead cable to the 14 pin Molex Microfit connector on the breakout PCB.

- Connect the remaining cables according to the following table:

| Breakout PCB | Cable label (breakout end) | Controller | Cable label (controller end) |

| E-MOTOR | E MOTOR | MOTOR5 | E STEPPER |

| TH0 | TH0 | T0/PF4 | HOTEND TH |

| CT | CT | T1/PF5 | CHAMBER TH |

| LED* | Not used | Not used | Not used |

| CFAN* | Not used | Not used | Not used |

| CFAN LED* | Not used | Not used | Not used |

*The three ports with labels CFAN, LED, CFAN LED are not used in the V2 build, they are used for Voron Switchwire.

The end result looks like this:

¶ Connecting the Toolhead Breakout Cables (Part 2)

In this step, we will finish making all the connections between the breakout PCB and the Octopus controller. Follow the table and diagram below:

| Breakout PCB | Cable label (breakout end) | Controller | Cable label (controller end) |

| PCF* | PCF | FAN0/PA8 | PART FAN |

| HEF* | HEF | FAN1/PE5 | HOTEND FAN |

| HE0 **** | HE0 | HE0/PA2 | BED_OUT |

| XES | XES | DIAG0/PG6 | X ENDSTOP |

| YES | YES | DIAG1/PG9 | Y ENDSTOP |

| ABL** | ABL | DIAG7/PG15 | Z PROBE |

*Pay special attention to the polarity/connection of the hotend, part fan, and hotend fan cables. Also double check the cables for any mistakes (they do occur from time to time). Any mistake here can cause a short circuit on the 24V power supply.

**The Z probe cable has the same 3pin JST-XH connectors on both ends but has a different pinout! Follow the table carefully and pay attention to the labels on the cable.

***The BED_OUT port in the Octopus controller carries more current than the HE ports, this allows you to use super high power hotends such as the Phaetus Rapido.

Once you connect everything between the breakout board and Octopus, check your wiring: specifically, use a multimeter and check that 24V/GND, and 5V/GND are not shorted. Mistakes in the cables or wirings can cause a short, which can result in damage to the PCBs if powered up. The result is below, you can also check out the close up photos of the breakout PCB and controller.

¶ Checkpoint #2

Before moving on to the next step, let us check all the breakout board wiring. Incorrect wiring or a mistake in the cabling here can cause serious damage to the breakout board and/or controller:

- As always, check all wiring with the machine unpowered and power cable unplugged.

- Double check the hotend cartridge cable. It is important that red wire is connected to + on both ends and black is connected to - on both ends.

- Check the polarity of the CT, TH0, XES, YES, cables. The black wire should be connected to the GND side of the connector on both ends.

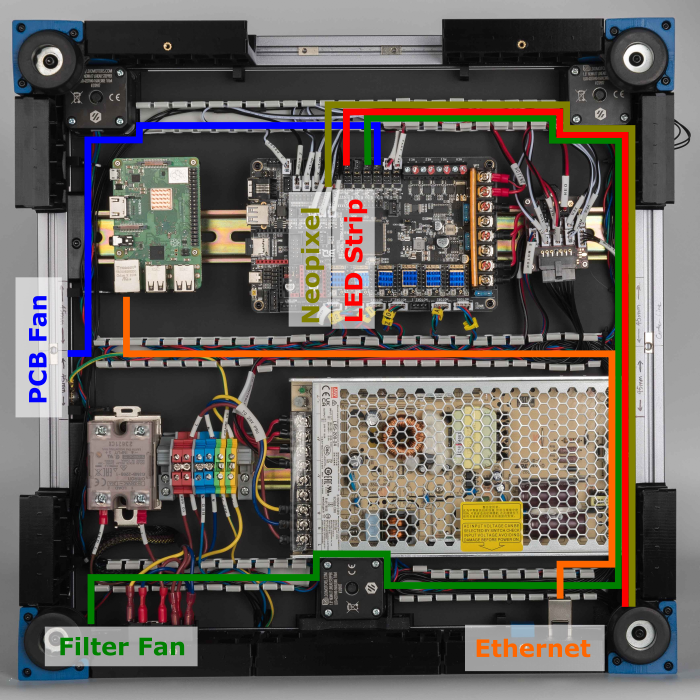

¶ Connecting the Filter, PCB Fans, LED strips, and Ethernet

In this step, we will connect the remaining Fans and LEDs, as well as the Neopixel and Ethernet Cable.

- Please remember to mount LED/Fan PCBs using the printed part to prevent a short with the extrusion.

- User the provided ethernet cable to connect the rear ethernet jack to the Raspberry Pi.

- Connect the remaining items according to the following table:

| Item | Cable Label | Controller Position |

| Electronic Compartment Fan* | PCB FAN | FAN2/PD12 |

| LED Strip | LED STRIP | FAN5/PD15 |

| Filter/Exhaust | FILTER FAN | FAN3/PD13 |

| Stealthburner Neopixel** | N/A | RGB_LED/PB0 |

* The PCB fans use a 3x2 XH splicer PCB to join two fans into a single cable, install the PCB onto the extrusion using a spacer and two M3x8 screws. See image of an installed PCB here.

**The neopixel connector on the Octopus is a simple red female header, consult this pin diagram when connecting. Pay close attention to polarity.

The result is below:

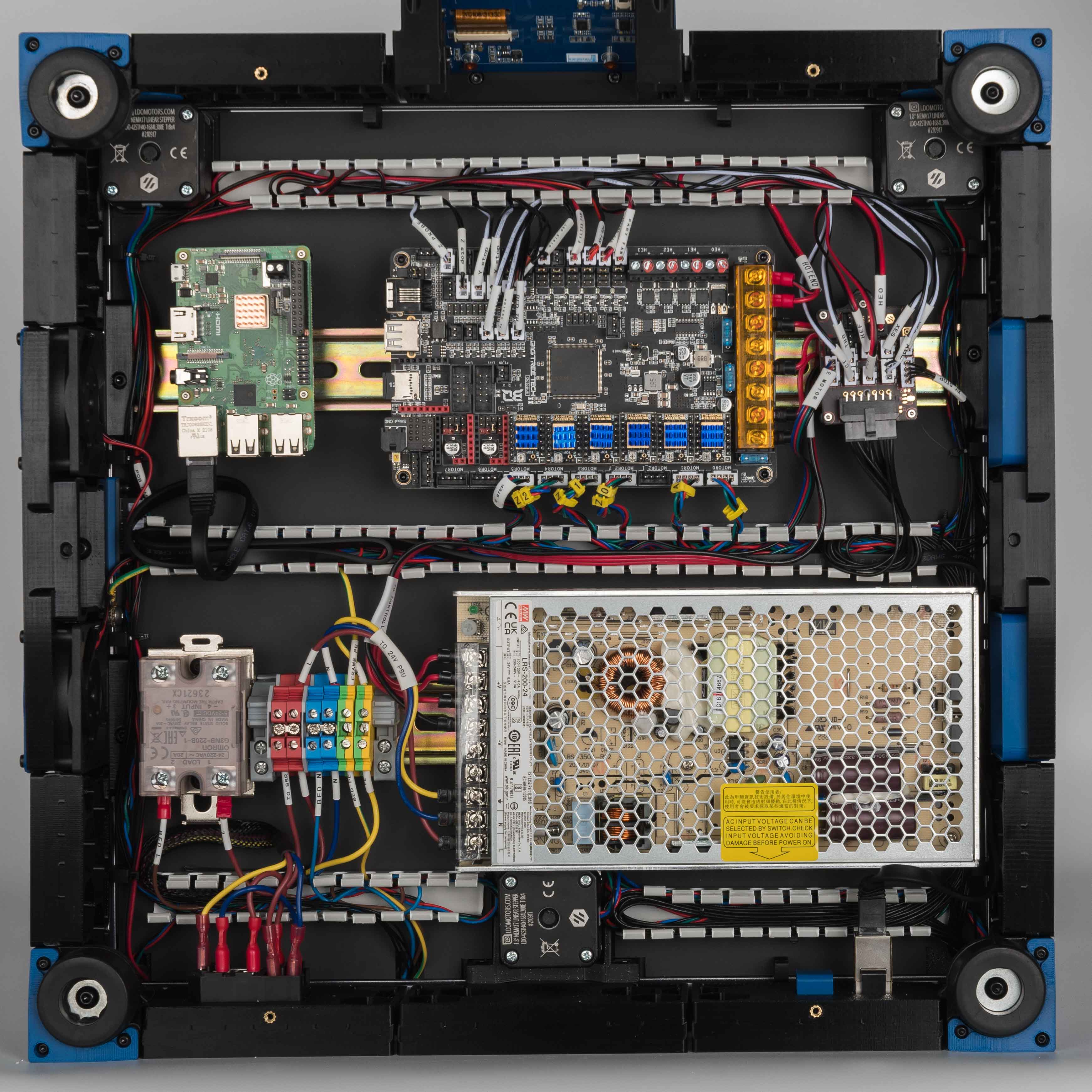

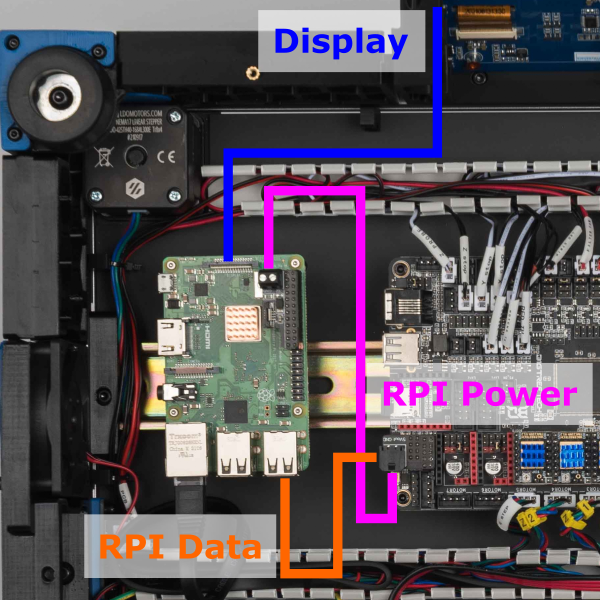

¶ Raspberry Pi Connections

In this short step we will make the connections between the Octopus and Raspberry Pi.

- Use the provided ribbon cable to connect the touch display to the Raspberry Pi. The ribbon cables need to be connected in a specific orientation - consult this photo and this photo (note the blue backing).

- Use the provided USB (angled) cable to connect the Octopus data port (USB C) to the Raspberry Pi (any USB A port).

- To ensure a solid powered connection to the Raspberry Pi, we will use the power terminal in the input shaper adapter. Consult the input shaper toolkit page for how to install the adapter onto the Raspberry Pi.

- We will use another adapter to breakout the connection to the Octopus - consult this photo.

- Finally use the provided cable to make the power connection between the Raspberry Pi and Octopus. Pay attention to polarity on the Raspberry Pi adapter.

The result:

¶ Finish Line

Congratulations! You have completed all the wiring, all that is left now is to cover up the wire ducts! We've posted a high resolution image here for you to compare your work.

¶ Next Steps - Software/Firmware

|

WARNING: Do not leave HE0 or HE1 connected. There have been reports of Octopus boards coming preloaded with a firmware that turns on all heaters and fans as soon as you power up the board. As a result, we recommend leaving the heaters disconnected until after loading the Klipper firmware |

Now that you've completed the electronics, it is time to follow the official Voron Software Installation. Follow BTT Octopus Software Configuration but remember to use the LDO Klipper config file which has been customized based on connections in this wiring guide.