¶ Introduction

Nitehawk-36 by LDO is a toolboard featuring RP2040 MCU, TMC2209 stepper drive, ADXL345 accelerometer, and USB port. Nitehawk-36's USB based connection method allows for a simple and easy setup compared to other CAN toolboards. The USB connnection also allows for a secondary USB port to connect your nozzle webcam or eddy current probe.

¶ Features

- Convenient wiring, no more complicated and error prone breakout cables - nitehawk only requires 24V power and a USB connector to the RPI host.

- USB Klipper connection, no additional software or hardware setup compared to CAN.

- Secondary USB port, an onboard USB port allows you to connect a second USB device to your toolhead without running an additional umbilical cable.

- Custom toolhead cable, a single combined USB data and power cable rated for drag chain use, but can also be used in umbilical configuration.

- Convenient Input Shaping, run input shaper calibration at anytime with an onboard accelerometer.

- Tacho enabled HEF, the hotend fan port is three pin tachometer compatible, allowing for additional diagnostics and safety.

¶ System Overview

The Nitehawk system consists of two PCBs and the Umbilical Cable. A simplified wiring diagram is shown below:

- Nitehawk-36, this is the main PCB, which houses the MCU, stepper driver, fan drivers, and other circuits.

- Umbilical Cable, this is a custom flex cable that is rated for drag chain use. It delivers 24V power to the main Nitehawk PCB while also carrying USB data.

- USB Adapter, this simple PCB combines 24V power from the power supply and USB data from the Raspberry Pi into a unified connection to the main Nitehawk PCB via the Umbilical cable.

¶ Printed Parts

¶ USB Adapter Mount

USB Adapter Mount, this is the mount for the USB adapter PCB. It is designed to be used with a standard Voron DIN clip and can be mounted in two different orientations. It also features a cover to reduce the chance of static discharge onto the PCB.

¶ Toolboard Mount

The mount for your toolboard will depend on the toolhead and specifically the extruder which the PCB is typically mounted behind. The following lists some of the toolboard mounts that are designed specifically for, or are compatible with Nitehawk-36:

- Universal Mount, a universal mount that allows the Nitehawk-36 to be mounted behind 36mm pancake motors at any orientation. Designed by camerony.

- Generic Orbiter 2 Mount, mounts the Nitehawk-36 to Orbiter 2. Should work on most toolheads.

- Xol + O2 Mount, a mount for the Xol toolhead with the Orbiter 2 extruder. Designed by jontek2.

- G2SA and WWG2 Mounts, mounts designed for Galileo Standalone (G2SA) and WristWatch G2 (WWG2) extruders. Design by Blamm based on works from Tetsu.

- Stealthchanger PCB36 Mount, is a mounting system specifically designed for StealthChanger toolheads. Designed by ThessienDSD.

- LGX Lite Rigid Mount, a minified mount for the LGX Lite and LGX Lite V2. Designed by EllaFoxo.

- Mini StealthBurner Rigid Mount, a rigid mount for the mini stealthburner on Voron 0. Designed by EllaFoxo.

- PUG mounts, a collection of PUG (printed umbilical gland) mounts for various extruders, compiled by Esoterical.

- Sherpa Micro Mount, a mount for Sherpa Micro, with a hinged umbilical guide, designed by oceanduck.

- Jabberwocky Mount, a mount for Jabberwocky toolheads.

- Anthead Mount, a mount for the Anthead toolhead, works with WristWatch G2 (WWG2) extruders. Designed by Jakecky.

If you designed a mount for Nitehawk-36 and wish for it to be highlighted here, please contact a member of the LDO team on Discord!

¶ Designing Your Own Mount

If you wish to design your own mount, we provide here some dimensions to reference:

¶ Klipper Config Files

A Klipper Configuation can be found in the Nitehawk-36 github repo here.

¶ Port and Pin Definitions

| Device/Port | PCB Label | Connector Type | RP2040 Pin | Description |

| E Motor | MOTOR | JST-XH2.5 4P | gpio23/24/25/0/1 (step/dir/ena/uart/tx) | A stepper motor port for the extruder. Driven by a TMC2209 chip. The current sense resistor is 100 mΩ. Enable is active low |

| Filament Sensor | JST-PH2.0 2P | gpio3 | Connects to the filament sensor. Supports switch based sensors only. | |

| Probe | PRB | JST-PH2.0 3P | gpio10 | Probe for bed leveling and/or Z sensing. |

| X Endstop | X-STOP | JST-PH2.0 2P | gpio13 | Connects to the X endstop. Supports switch based endstops only. |

| Part Fan | PCF | JST-PH2.0 2P | gpio6 | Connects to part cooling fan. |

| Hotend Fan | HEF | JST-PH2.0 3P | gpio5/16 (fan/tacho) | Connects to hotend fan. The fan control pin is gpio5 and the tachometer sensor pin is gpio16. |

| Aux. Port | (P12) | JST-PH2.0 2P (unpopulated) | This is an unpopulated port that can be optionally soldered with a PH2.0 connector. It can be used as an always-on 24V fan port. | |

| PCF Voltage Selector | 2.0mm Jumper | Selects the supply voltage of the part fan. Selection of 24V or 5V. | ||

| HEF Voltage Selector | 2.0mm Jumper | Selects the supply voltage of the hotend fan. Selection of 24V or 5V. | ||

| Probe Votage Selector | 2.0mm Jumper | Selects the supply voltage of the probe port. Selection of 24V or 5V. | ||

| USB Expansion Port | JST-ZH1.5 5P | Allows connection to a secondary USB device. | ||

| Neopixel | JST-PH2.0 3P | gpio7 | Connects to neopixel LEDs. | |

| Hotend Heater | HE0 | E0506 Ferrule | gpio9 | Connects to the hotend heater. |

| Hotend Thermistor | TH0 | JST-PH2.0 2P | gpio29 | Connects to the hotend thermistor. Uses a 2.2kΩ pull up resistor. |

| Activity LED | ACT | gpio8 | A small software controlled onboard LED. Active low. | |

| Accelerometer | gpio27/18/20/19 (cs/clk/mosi/miso) | ADXL345 accelerometer for input shaping. Controlled via software SPI. | ||

| Toolhead Cable | XT30(2+2) | A USB port for toolhead. |

¶ Electrical Specifications

| Parameter | Symbol | Minimum | Typical | Maximum | Unit | Comments |

| Power Supply Input | Vin | 20 | 24 | 28 | V | power input for the toolboard. |

| Temperature | Tenv | 65* | °C | operating ambient temperature | ||

| 5V Current | Irpi | 5 | A | current output for the 5V buck converter. | ||

| Fan Current | Ifan | 1 | A | current rating for each fan port (HEF and PCF). |

*This was previously incorrectly marked 85°C. Note that board temperature is also influenced by heat from the extruder motor and the onboard stepper drive.

Note: The max wattage is 120W.

Note: If the rated current of your stepper motor is 1A, we recommend setting it below 0.7A. If you need more than 0.7A, please add extra heat dissipation for your board.

¶ Operating Environment

Nitehawk-36 has been tested to operate in enclosed printer environments with temperatures of up to 65°C. However, this is a nominal temperature rating of which many factors will influence the actual temperature on your toolboard:

- Stepper Motor Current. Setting the current of the onboard TMC2209 to above 0.6A can raise the temperature of your toolboard. Additionally, heat from stepper motors running high current can be transferred to your toolboard if they are mounted close together.

- High hotend Power. Using a high powered hotend and/or setting very high hotend temperatures in your prints can raise the temperature of your toolboard.

- Enclosures. Enclosing your toolboard can worsen air convection and cause your toolboard to heat up over the span of a print.

- Active Cooling. Using active cooling (i.e. fans) can help keep the temperature of your toolboard low. This can help conteract the other factors that heat up the toolboard.

Note that elevated operating temperatures can reduce the lifespan of components (mosfets, power supplies, microcontrollers) on your toolboard.

¶ Umbilical Cable

¶ Connector Variants (Toolboard side)

The connector used at the toolboard side is Amass XT30(2+2)-F. You may encounter three variants. all variants are compatible with Nitehawk-36, Nitehawk-SB, and Orbitool Toolboards but have different form factors,

- Fully Overmolded, this is the default version shipped with the Nitehawk-36 KIT Rev C and later. It offers good strain relief but does not have the same flexibility at the connector end as variants #2 or #3.

- Note: This version is NOT included in the recall since it would have further delayed the replacement of the defective boards. We apologize for any confusion. We are working to produce more and will offer them at cost to existing customers once they become available.

- Partially Overmolded, this is the default version that is shipped with Nitehawk-SB and Voron kits. This version has a length of exposed wiring which allows the cable to bend easily at the toolboard side (needed when using Stealthburner + cable chains)

- Potted, this variant shipped with the old Nitehawk-36 V1.2 and Nitehawk-SB kits. This variant has now been replaced by variant #1 and #2.

*The rated bend radius of the cable is 28mm and the nominal remperature of the cable is 105C.

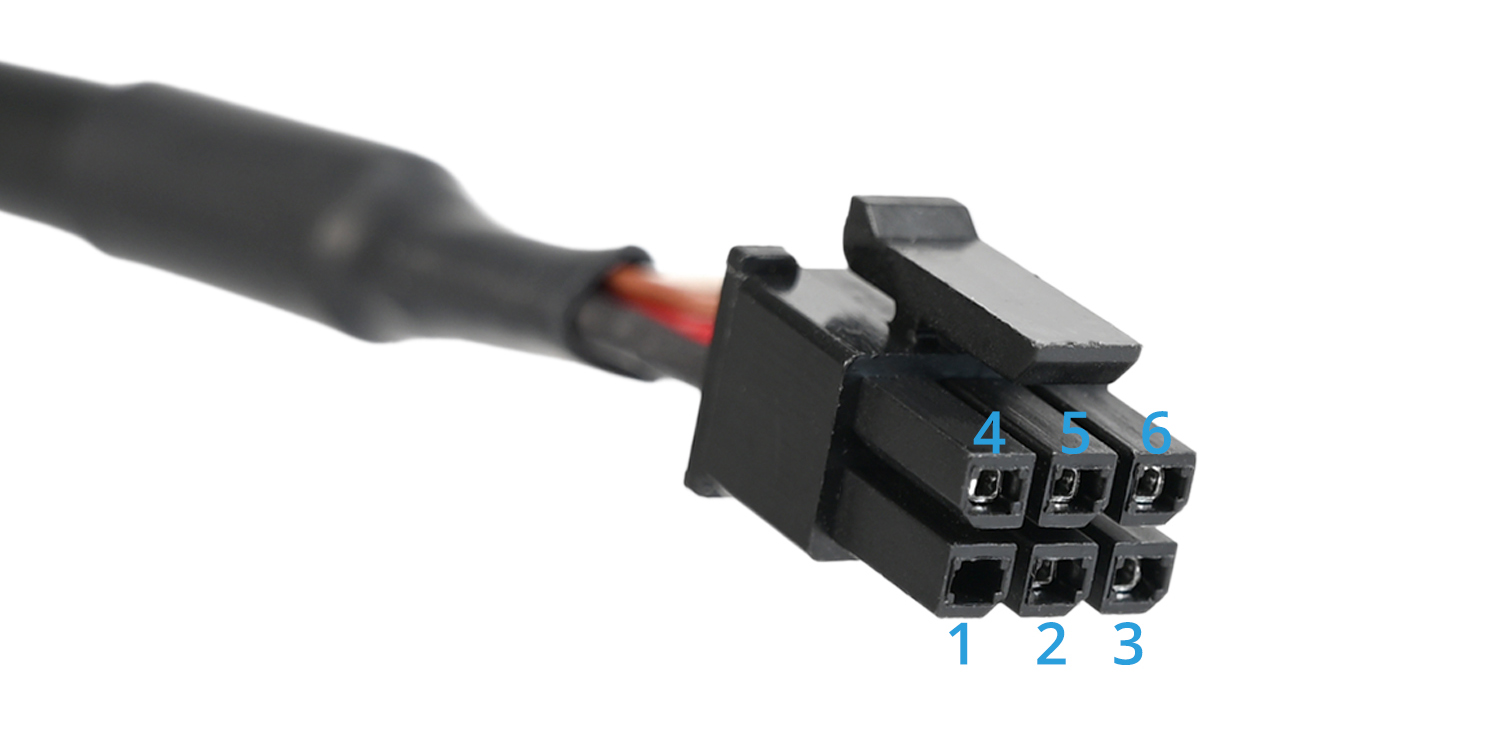

¶ Cable Pinout (Toolboard Side)

The following shows the detailed pinout of the XT30 connector:

| Pin # | Name | Colour | Description |

| 1 | GND/Shielding | Black | Cable shielding and GND on the PCB share this pin. |

| 2 | 24V | Red | Provides 24V power to the toolboard. |

| 3 | D+ | Brown/Green | USB Data +. This conductor may be brown or green depending on batch. |

| 4 | D- | White | USB Data - |

¶ Cable Pinout (Adapter Side)

Micro-Fit 3.0 is the connector used at the USB adapter side of the umbilical cable. This connector is fairly easy to crimp and allows for the cable to be easily shortened if needed. Never plug or unplug this connector when the machine is powered! Doing so may risk damage to the Nitehawk or your Host (Raspberry Pi). The following shows the detailed pinout of the connector:

| Pin # | Name | Colour | Description |

| 1 | NC/GND | This pin is not connected at the cable, but is connected to GND on the PCB. | |

| 2 | NC/Shielding/GND | Cable shielding is connected to GND on the PCB. In newer versions this pin is not used. | |

| 3 | GND | Black | In newer versions, GND and shielding share the same conductor. |

| 4 | D+ | Brown/Green | USB Data +. This conductor may be brown or green depending on batch. |

| 5 | D- | White | USB Data - |

| 6 | 24V | Red | Provides 24V power to the toolboard. |

¶ Firmware Setup and Update

The firmware for Nitehawk consists of two components: Katapult and Klipper. Katapult is a bootloader designed specifically for Klipper, it ensures that the software on the RP2040 MCU boots up smoothly and allows for easy updating of the Klipper firmware. You can learn more about Katapult here. Klipper is the main firmware that runs on the RP2040 MCU, you can learn more here.

Your Nitehawk will come shipped with both Katapult and Klipper installed. Ideally, you will only ever need to occasionally update the Klipper firmware and never have to touch Katapult. If the Katapult bootloader was erased or is not present for any reason, you can check this below Installing the Katapult Bootloader section for instructions on how to reupload Katapult.

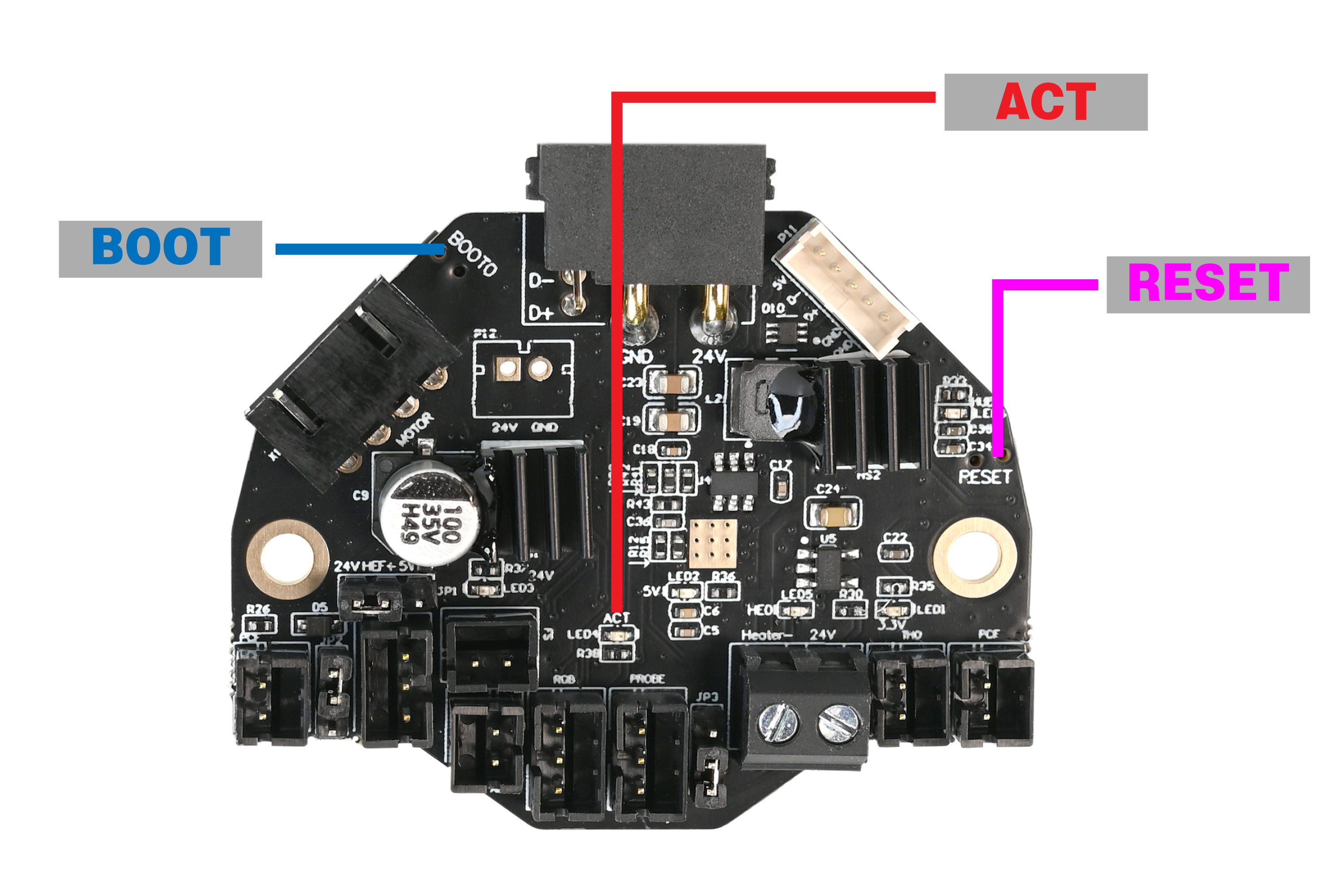

¶ Hardware Setup

No special setup is required for installing either Klipper or Katapult. Nitehawk simply needs to be hooked up as it operates normally in your 3D printer, with the toolboard connected to your Klipper host device (e.g. Raspberry Pi) via the USB adapter board. You also need access to the two buttons (RESET and BOOT0) on the toolboard. Also ACT light are important later. Reference the photo below to find the buttons and the ACT light.

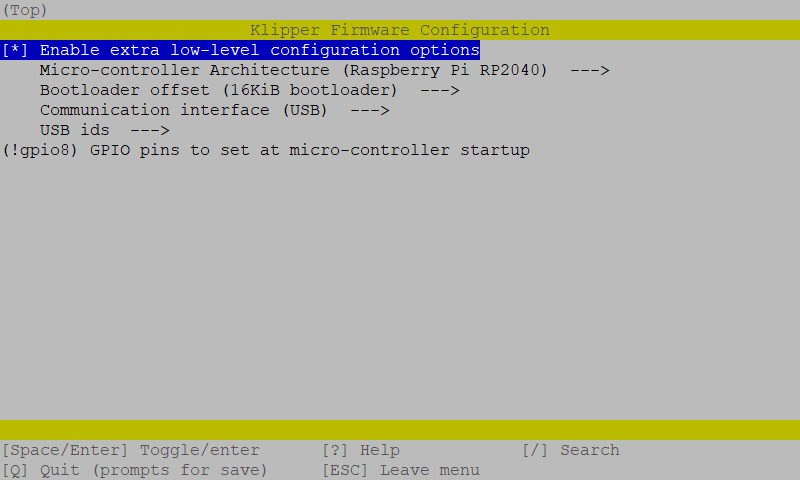

¶ Compiling Klipper Firmware

The following instructions are for compiling and upload new Klipper firmware to your Nitehawk toolboard. You need to perform these steps if you want to update your klipper firmware to the newest version or if you are doing a fresh install and just uploaded Katapult (see the previous sections). Before compiling the firmware, you will need to have Klipper already installed on your host device (e.g. Raspberry Pi).

- Log on to your Klipper host via SSH, windows users can use putty or any other SSH client. Mac and Linux users can simply connect with the

sshcommand in their command line terminal. Run the following commands to open the firmware configuration interface:

cd ~/klipper

make menuconfigIn the configurator, Enable extra low-level configuration options, choose Raspberry Pi RP2040, match the rest of the settings with the screenshot below:

- Most importantly, make sure you set the

16KiB bootloaderoffset. Otherwise you will erase the Katapult bootloader! - Enter

Qto quit and confirm withYes when prompted to save. And run the following to generate the firmware file:

make clean

makeA firmware file called will now be generated and can be located in the directory ~/klipper/out. You are now ready to upload this firmware to the Nitehawk toolboard. The recommended method is uploading via the make flash command.

¶ Uploading Klipper (via make flash)

- Run

ls /dev/serial/by-idto find the USB ID of your Nitehawk toolboard. The USB ID should have a format similar to this:usb-Klipper_rp2040_1234567890000000-if00. - Run the following commands. This will install the

python,pip, and thepyserialpython module if it is not present. You may receive anerror: externally managed environmentwhen running the last command. This simply meanspyserialhas already been installed and you may move on to the next step.

sudo apt install python3 python3-pip

pip install pyserialRun the following commands to upload the firmware to the MCU directly:

cd ~/klipper

sudo service klipper stop

make flash FLASH_DEVICE=/dev/serial/by-id/<your USB ID>

sudo service klipper startIf you encounter any connection issues after flashing the new firmware, reboot your printer. Your toolboard should now have the newest firmware. If the flashing process failed, you may want to try using the the second method and upload Klipper via Katapult

¶ Uploading Klipper (via Katapult)

In this section we will use an alternative method to upload klipper firmware using the Katapult bootloader. If your toolboad is missing the Katapult bootloader for any reason, you should follow the next section to install it first.

- First we will check and install the Katapult package (if necessary):

test -e ~/katapult && (cd ~/katapult && git pull) || (cd ~ && git clone https://github.com/Arksine/katapult) ; cd ~To upload Klipper, we will use a Python script to communicate with the Katapult bootloader inside of the Nitehawk Toolboard. First, we will first need to setup a Python3 environment. Run the following:

virtualenv -p python3 ~/katapult-env

~/katapult-env/bin/pip3 install pyserialThis creates a Python 3 environment in the location ~/katapult-env/ and installs the module pyserial which is required to run the upload script.

- Now we must force Nitehawk to enter the Katapult bootloader and obtain the USB serial address. Start by quickly double clicking the RESET button, you should see the ACT light blinking slowly.

- Next run

ls /dev/serial/by-id/. You should see something likeusb-katapult_rp2040_A1234567898D1234-if00- note that the address contains the wordkatapult. If not, this means either your Nitehawk did not have Katapult installed or you did not enter the Katapult bootloader properly. Copy the address down for the next step, do not exit the bootloader yet. - Finally run the following but substituting the address with the one you obtained in the previous step. If everything was correct, you should see some write and verification progress followed by

Flash Successat the end.

~/katapult-env/bin/python3 ~/katapult/scripts/flashtool.py -d /dev/serial/by-id/usb-katapult_rp2040_A1234567898D1234-if00As a finally verification, run ls /dev/serial/by-id/. you should see a Klipper USB serial address in the form of usb-Klipper_rp2040_E1234567A12D9835-if00.

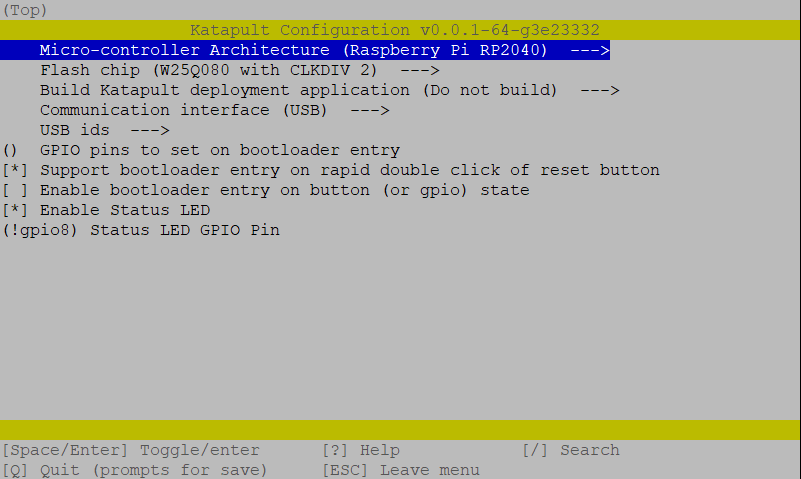

¶ Installing the Katapult Bootloader

In this section we will compile and upload the Katapult Bootloader. Note that your Nitehawk toolboard normally ships with Katapult pre-installed and you only need to perform the following operations if Katapult was inadvertently overwritten or lost.

- Login to the Raspberry Pi. We will check and download the Katapult package (if necessary):

test -e ~/katapult && (cd ~/katapult && git pull) || (cd ~ && git clone https://github.com/Arksine/katapult) ; cd ~Now we will configure need to configure some options:

cd ~/katapult

make menuconfigThis will bring us to the configuration menu. Make sure to set the options as below:

- Enter

Qto quit and confirm withYes when prompted to save. next run the following command to compile and generate the Katapult binary files:

make clean

makeA binary file called katapult.uf2 will now be created in the location ~/katapult/out/. Our next job is to upload this file into the RP2040 MCU on the Nitehawk toolboard.

- We now need to reboot the Nitehawk toolboard into system boot mode. This is done in three steps:

- Press and hold both the RESET and BOOT0 button.

- Release the RESET button

- Release the BOOT0 button

- If done correctly, your Nitehawk should now have entered boot mode and become a sort of semi “thumbdrive”. Run the command

ls /dev/sda*to confirm. You should see something like/dev/sda/ dev/sda1. If you get something likels: cannot access '/dev/sda*': No such file or directorythis means either Nitehawk didn't enter boot mode or there is a problem with the physical connection between the Raspberry Pi and Nitehawk. - We are now finally ready to upload Katapult. Run following commands:

sudo mkdir -p /mnt/pico

sudo mount /dev/sda1 /mnt/pico

sudo cp ~/katapult/out/katapult.uf2 /mnt/pico

sudo sync

sudo umount /mnt/picoThe above commands basically mount the Nitehawk as a storage drive and copies the katapult binary files into that drive. It then unmounts the drive. If everything went smoothly, you should now be able to see the ACT light located below the BOOT0 button blink slowly. To double check that Katapult is installed, run ls /dev/serial/by-id. You should see something like: usb-katapult_rp2040_A1234567898D1234-if00which is USB serial address of Nitehawk running Katapult. A few small details to note here:

- You will only see this address when Nitehawk is in Katapult bootloader mode and not in system boot mode or when Nitehawk is normally running Klipper.

- You can force Nitehawk to enter the Katapult bootloader by quickly double clicking the RESET button on the toolboard. The ACT light blinks slowly in this mode as previously mentioned.

- You will need enter the Katapult bootloader and the Katapult USB serial address to upload Klipper.

- By following the above instructions, you will have uploaded Katapult but erased all other firmware, including any previously installed Klipper firmware.

- Exit the Katapult bootloader by single pressing the RESET button, normally you would enter Klipper firmware. Since you just erased Klipper, you will just re-enter the Katapult bootloader.

- you are now ready to compile and upload Klipper - see the previous section here.

¶ What's included in the kit?

| Items | QTY |

| Toolhead PCB | 1 |

| USB Adapter PCB | 1 |

| USB Umbilical Cable 2.15m | 1 |

| USB-A to USB-C Data Cable, 0.4m | 1 |

| 24V Power Cable | 1 |

| USB Hookup Cable | 1 |

| Self-Tapping Screw, M2x10 | 3 |

| Machine Screw, SHCS, M3x8 | 2 |

| Machine Screw, SHCS, M3x12 | 4 |

| MicroFit3 style Male Connector, 3x2pin | 1 |

| MicroFit3 style Female Crimp Terminal | 8 |

| XH2.5 Female Connector, 4pin | 1 |

| XH2.5 Female Crimp Terminal | 8 |

| PH2.0 Female Connector, 2pin | 5 |

| PH2.0 Female Connector, 3pin | 3 |

| PH2.0 Female Crimp Terminal | 30 |

| Ferrule, 1008 | 4 |

| Ferrule, 0508 | 4 |